Iyini i-Multistage Centrifugal Pump?

A iphampu ye-centrifugal enezigaba eziningiiwuhlobo lwepompo eklanyelwe ukuhambisa uketshezi ngokusebenza kahle okuphezulu kanye nomfutho okhulayo. Iqukethe ama-impeller amaningi ahlelwe ngochungechunge, ngalinye linikela kumfutho ophelele okhiqizwayo. Iphampu isetshenziswa ngokuyinhloko ezinhlelweni ezidinga ikhanda eliphezulu—okusho ukuthi iphampu idinga ukuphakamisa uketshezi luye ezindaweni eziphakeme noma ukuluhambisa ebangeni elide. Lawa maphampu avame ukubonakala ezinhlelweni zezimboni lapho inani elibalulekile lamandla lidingeka khona ukuze kunqobe ukulahlekelwa kwengcindezi noma ukuphakamisa uketshezi ngokumelene namandla adonsela phansi.

I-impeller ngayinye, noma isiteji, empompini yezigaba eziningi isebenza ngokuhambisana, futhi isigaba ngasinye esilandelayo sakhela phezu kokucindezela okudalwe yileso sangaphambilini. Njengoba uketshezi luhamba ku-impeller ngayinye, isivinini salo siyakhuphuka, okuholela ekunyukeni okuphelele kokucindezela ngesikhathi uketshezi luphuma epompo. Lo mshini wenza amaphampu e-multistage centrifugal alungele izinhlelo zokusebenza lapho iphampu yesiteji esisodwa ingakwazi ukunikeza ikhanda elidingekayo.

Izicelo zeI-Multistage Pumps embonini

Ukubaluleka kwamaphampu aphakathi kwezigaba eziningi angeke kweqiswe, ikakhulukazi ezimbonini ezifana nokuhlanza amanzi, ukucutshungulwa kwamakhemikhali, ukukhiqizwa kwamandla, kanye nowoyela negesi. Lawa maphampu aziswa kakhulu ngenxa yekhono lawo lokugcina ukusebenza kahle okuphezulu ezikhathini ezinde zokusebenza kanye nezimo ezinzima. Ezikhungweni zokuhlanza amanzi, amaphampu esiteji esiningi asetshenziselwa ukucindezela amanzi ukuze afinyelele amazinga ahlukene okuhlunga noma ukuthutha amanzi amabanga amade kubathengi. Emkhakheni kawoyela negesi, zibalulekile ekuthutheni uwoyela ongahluziwe, igesi yemvelo, kanye nemikhiqizo ecolisisiwe ngamapayipi noma phakathi kwezindawo ezicutshungulwayo.

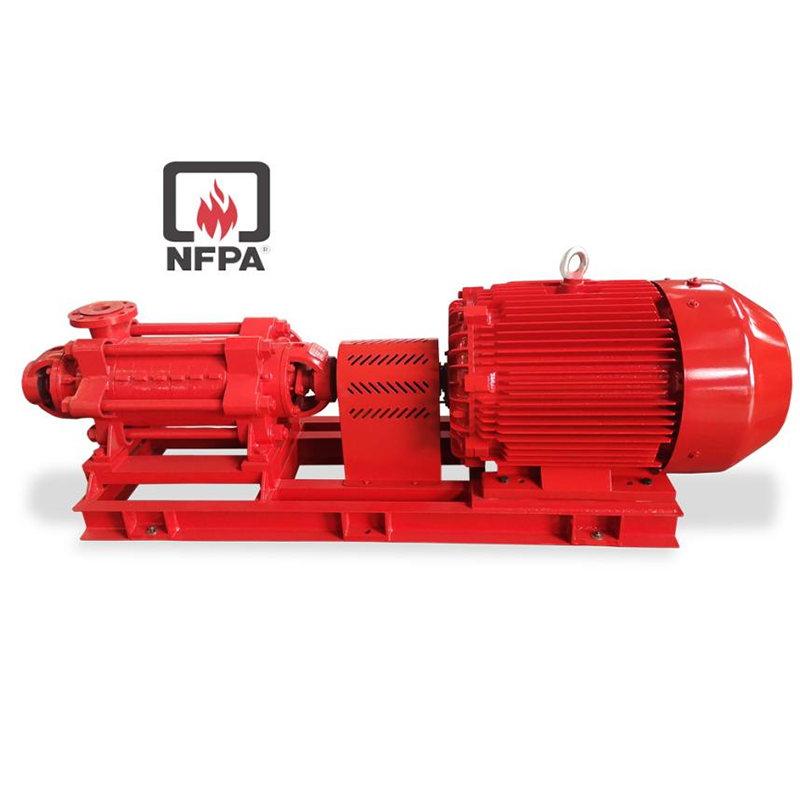

Ngaphezu kwalokho, ukuguquguquka kwazo kudlulela ezinhlelweni zokusebenza lapho isistimu yokumpompa kufanele igcine ukugeleza okuzinzile naphezu kokuhlukahluka kwesidingo. Amaphampu we-Multistage atholakala ezinhlelweni zokucisha umlilo, izinhlelo ze-HVAC, ngisho nakumaphrojekthi amakhulu okunisela. Ukuzivumelanisa nezimo kubenza babaluleke kuzo zonke izimboni eziningi ezithembele ekuphatheni uketshezi olunomfutho ophezulu.

Isimiso Esiyisisekelo sokuSebenza samaphampu aseCentrifugal

Iqhaza Le-Centrifugal Force ku-Fluid Movement

Enhliziyweni yayo yonke impompo ye-centrifugal kukhona amandla amaphakathi akhiqizwa i-impeller. Lapho uketshezi lungena empompini, luqondiswa phakathi nendawo ye-impeller. Ama-impeller blades ayazungeza, okwenza uketshezi luphonswe ngaphandle ngomjikelezo we-impeller. Lesi senzo sisheshisa uketshezi futhi siguqule amandla emishini abe amandla e-kinetic, okudala ukwanda kwengcindezi. I-centrifugal force iphoqa uketshezi ukuthi lusuke phakathi nendawo, okuholela ekudalweni kwezindawo ezinomfutho ophezulu emaphethelweni angaphandle epompo.

Lo mehluko wengcindezi udala ukuthi uketshezi lugeleze lusuka ohlangothini lwe-inlet olunomfutho ophansi luye ohlangothini lwe-high-pressure outlet, okuvumela ukuhamba okuqhubekayo koketshezi. Ukusebenza kahle kwalokhu kudlulisa kuncike ezintweni ezifana nesivinini se-impeller, ukwakheka kwendlu yephampu, kanye nohlobo loketshezi olumpontshwayo.

Izingxenye Ezibalulekile Zephampu Ye-Centrifugal

Iphampu ye-centrifugal ngokuvamile iqukethe izingxenye ezimbalwa ezibalulekile ezisebenza ndawonye ukuze kuqinisekiswe ukusebenza kahle. Lokhu kubandakanya:

- Impeller: Ingxenye ejikelezayo enesibopho sokudlulisela amandla e-kinetic oketshezini.

- Isikhwama: Igobolondo langaphandle elizungeza i-impeller, eliqondisa ukugeleza koketshezi ngepompo.

- Ama-Nozzles okumunca nokukhipha: Indawo yokungena nokuphuma lapho uketshezi lungena luphinde luphume khona epompo.

- Umphini: Ukuxhumanisa kwemishini okuxhuma i-impeller kumotho, idlulisela amandla ajikelezayo.

- Ama-Bearings kanye nezimpawu: Izingxenye ezinciphisa ukungqubuzana futhi zivikele ukuvuza, ziqinisekisa ukusebenza okushelelayo nokusebenza kahle.

Ndawonye, lezi zingxenye zisebenza ngokuvumelana ukuze kuqinisekiswe ukunyakaza okuqhubekayo koketshezi kuyilapho kunciphisa ukulahlekelwa kwamandla.

I-Fluid Isheshisa Futhi Iqondiswa kanjani ngaphakathi kwePump

Njengoba i-impeller ijikeleza, idlulisela amandla e-kinetic oketshezini. I-casing yepompo iklanyelwe ukuguqula la mandla e-kinetic abe amandla okucindezela. Uketshezi lunyakaza ngaphandle nge-volute (noma i-diffuser), olunciphisa kancane kancane isivinini soketshezi kuyilapho lukhulisa umfutho walo. Uketshezi lube seluphuma epompo ngomfutho omkhulu, lulungele ukulethwa engxenyeni elandelayo yesistimu. Lokhu kuguqulwa kusuka kumandla e-kinetic kuya kumandla okucindezela yikhona okwenza amaphampu amaphakathi aphumelele kakhulu ekuthuthweni koketshezi ebangeni nobude obuhlukahlukene.

I-Multistage Design: Ihluke Kanjani Kumaphampu Esiteji Esisodwa

Izinzuzo Zokusebenzisa Izigaba Eziningi Ezinhlelweni Zokumpompa

Inzuzo eyinhloko yamaphampu esiteji esiningi isemandleni awo okukhiqiza izingcindezi eziphakeme, okubalulekile ekusebenzeni lapho uketshezi ludinga ukuhanjiswa amabanga amade noma luye ezindaweni eziphakeme. Ngokusebenzisa izigaba eziningi, lawa maphampu asabalalisa ukukhuphuka kwengcindezi ezigabeni ezimbalwa, ehlisa ubunzima kunoma iyiphi i-impeller eyodwa futhi athuthukise ukusebenza kahle okuphelele kwesistimu.

Ukwengeza, amaphampu esiteji esiningi ajwayele ukubumbana futhi angabizi kakhulu kunokusebenzisa amaphampu amaningi esiteji esisodwa ngokuhambisana. Futhi zihlinzeka ngokusebenza okushelelayo njengoba i-impeller ngayinye isebenza ngaphakathi kwebanga elifanele lengcindezi, inciphisa ukuguga nokudabuka.

Izimboni Ezijwayelekile Ezithembele Kumaphampu e-Multistage

Amaphampu we-Multistage centrifugal abalulekile ezimbonini ezahlukahlukene. Embonini yokuhlanza amanzi namanzi angcolile, asetshenziselwa ukukhulisa umfutho wamanzi kanye nezinhlelo zokuhlunga kwe-osmosis ehlehlayo. Kuwoyela negesi, asebenza kuzo zombili izinhlelo zokusebenza ezikhuphuka nomfula, kusukela ekumpompeni uwoyela ongahluziwe kuya ekuletheni imikhiqizo ecolisisiwe ezindaweni zokugcina. Ezinye izimboni ezibalulekile ezithembele kumaphampu ezigaba eziningi zihlanganisa ezemithi, ukucubungula ukudla, izimayini, nezinhlelo zokuvikela umlilo.

Ukuqonda Inqubo Yokupompa Kumaphampu e-Multistage

Ukungena Kwamanzi noma Okuwuketshezi kanye Nomfutho Wokuqala Esigabeni Sokuqala

Inqubo iqala lapho uketshezi lungena empompini ngombhobho wokumunca. Esigabeni sokuqala, i-impeller ithola uketshezi futhi iqala ukuyidlulisela isivinini. I-centrifugal force iphushela uketshezi ngaphandle, lapho luqondiswe khona endaweni yephampu. I-casing bese idlulisela uketshezi ku-impeller elandelayo, lapho ingcindezi iqala ukwakha.

Iqhaza Lesiteji Ngasinye Ekwakheni Ingcindezi

Njengoba uketshezi ludlula esigabeni ngasinye, umfutho uyaqhubeka nokwanda. I-impeller yokuqala ingase yengeze inani elincane lokucindezela, kodwa ama-impeller alandelayo anikela ngokuqhubekayo emazingeni aphezulu okucindezela. Ngesikhathi uketshezi lufika esigabeni sokugcina, lusuke selucindezelekile lwafinyelela ezingeni elidingekayo, lulungele ukukhishwa.

Inani eliqondile lezigaba ezidingekayo lincike ezidingweni ezithile zohlelo. Isibonelo, uma isistimu idinga ikhanda elingamamitha angu-200, iphampu enezigaba ezimbili ingase ikhiqize amafidi angu-100 ekhanda ngesiteji ngasinye, kuyilapho iphampu enezigaba ezine izokhiqiza amafidi angu-50 ngesiteji ngasinye, isabalalise umthwalo ngokuphumelelayo.

Ingcindezi Ilethwa Kanjani Kusistimu

Uma uketshezi seludlule ku-impeller yokugcina, luphuma epompo ngengcindezi oyifunayo kanye nezinga lokugeleza. Umbhobho okhiphayo uqondisa uketshezi kusistimu, okungase kuhlanganise amapayipi, amathangi okugcina, nanoma iyiphi enye ingxenye edinga uketshezi olunomfutho. Yonke le nqubo iqinisekisa ukuthi uketshezi luthuthwa ngokulahlekelwa okuncane kwamandla kanye nokucindezela okungaguquki.

Izinto Ezithonya Ukusebenza Kwephampu ye-Multistage Centrifugal

Izinto ezimbalwa zangaphandle zingathonya ukusebenza kwephampu ye-centrifugal enezigaba eziningi. Isibonelo, isivinini se-impeller sithinta amandla e-kinetic anikezwa oketshezini, ngaleyo ndlela kuthinte kokubili ukugeleza nokucindezela. I-fluid viscosity idlala indima ebalulekile njengoba uketshezi olujiyile ludinga amandla engeziwe ukuze lunyakaze, olunganciphisa ukusebenza kahle kwephampu. Ukwengeza, ukuguquka kwezinga lokushisa kungashintsha izici zoketshezi, okuholela ekuhlukeni kokusebenza kwepompo, ikakhulukazi uma kusebenzisana nezinto ezizwelayo lokushisa.

Ungayikhetha nini i-Multistage Centrifugal Pump

Ukukhetha iphampu ye-multistage centrifugal efanele kuhilela ukucabangela izici ezifana nekhanda elidingekayo, izinga lokugeleza, nezici zoketshezi. Ukwengeza, izidingo ezithile zohlelo lokusebenza, ezifana nokusebenza kahle kwamandla, izithiyo zesikhala, nokuqina, kufanele zihlolwe. Uma kudingeka ukulethwa komfutho ophezulu, ikakhulukazi kumasistimu anezidingo zokuthutha eziphakeme kakhulu noma amabanga amade, iphampu ye-centrifugal enezigaba eziningi ngokuvamile iyisinqumo esifanelekile.

I-Vertical vs Horizontal Multistage Pump

Ukubaluleka Kokukhetha Ukucushwa Okulungile

Ukukhetha phakathi kwepompo emile noma evundlile ye-multistage akuyona nje indaba yokukhetha; kuyisinqumo esibalulekile esithinta ukusebenza kahle konke, ubude besikhathi sokuphila, kanye nokuphumelela kwezindleko zesistimu yokumpompa. Ukukhetha okulungile kuncike ezintweni eziningi, okuhlanganisa isikhala esitholakalayo sokufakwa, ingcindezi edingekayo kanye namazinga okugeleza, kanye nohlobo loketshezi olumpontshwayo. Ukuqonda umehluko wokuklama kanye nezimo zohlelo lokusebenza zohlobo ngalunye lwephampu kuyisihluthulelo sokwenza isinqumo esifanele.

Umehluko Wedizayini Phakathi Kwamaphampu Aqondile Navundlile

Ukwakhiwa kanye nesakhiwo seIphampu ye-Vertical Multistage

Amaphampu e-multistage amile aklanywe nge-shaft eqondile exhuma injini kuma-impeller wepompo. Idizayini ivamise ukuba nezigaba ezistakiwe ezihlala phezu kwesinye, uketshezi ludonselwa empompini ukusuka phansi bese lukhishwa phezulu. Lawa maphampu ngokuvamile aminyene futhi alungele izimo lapho ukuphakama, esikhundleni sendawo yaphansi, kuyisici esikhawulelayo. Zivamise ukugxunyekwa emithonjeni, emathangini, noma kwezinye izindawo eziqondile, kusetshenziswa amandla adonsela phansi ukuze zisize ekuthatheni uketshezi.

Idizayini eqondile iwusizo ikakhulukazi ezinhlelweni ezidinga ukuphuma kwengcindezi ephezulu, njengokumpompa okujulile noma lapho iphampu idinga ukuphatha ikhanda elime mpo elibalulekile. Isakhiwo sakhelwe ukukhulisa ukusebenza kahle ngokunikeza indlela ecacile, eqondile ukuze uketshezi luhambe, kuncishiswe ukulahlekelwa kwamandla.

Ukwakhiwa kanye nesakhiwo seIphampu ye-Multistage Evundliles

Ngokuphambene, amaphampu e-multistage avundlile afaka shaft evundlile exhuma injini kuma-impeller. Lawa maphampu avamise ukuba banzi futhi made kunamamodeli aqondile, futhi izigaba ziqondaniswe ngapha nangapha. Amaphampu avundlile ngokuvamile anesisekelo esizinzile futhi kulula ukuwanakekela ngenxa yokwakheka kwawo okuqondile. Isakhiwo siqinisekisa ukuthi uketshezi lugeleza ngendlela evundlile, elungele izinhlelo zokusebenza lapho iphampu kufanele ibambe amavolumu amakhulu noma lapho ukuhlelwa okuqondile okuhlangene kungenzeki khona.

Idizayini evundlile ngokuvamile isetshenziswa ezindaweni zezimboni lapho isikhala singenakukhathazeka kangako, kodwa iphampu kufanele ihlanganise amazinga okugeleza aphezulu noma lapho iphampu kufanele ibekwe endaweni evundlile ngenxa yezidingo zesistimu.

Izinzuzo kanye Nemibi Yamaphampu e-Vertical Multistage

Izinzuzo Amaphampu Aqondile

Amaphampu esiteji amaningi aqondile anikeza izinzuzo ezimbalwa ezihlukile. Enye yezinzuzo eziyinhloko usayizi wabo ohlangene. Lawa maphampu alungele izindawo ezinendawo evundlile elinganiselwe, njengokufakwa komthombo ojulile noma izindawo lapho kudingeka khona unyawo oluncane. Idizayini iphinde yehlise inani lomsebenzi wemishini odingekayo ukuze kuhanjiswe uketshezi lubheke phezulu, ikakhulukazi ezinhlelweni ezijulile.

Ukwengeza, amaphampu aqondile ngokuvamile adinga izisekelo ezimbalwa kanye nosekelo oluncane lwesakhiwo uma kuqhathaniswa namaphampu avundlile, okuwenza kube lula ukuwafaka ezinhlelweni ezithile. Idizayini yabo ibavumela ukuthi baphathe ngokuphumelelayo ukucindezela okuphezulu, izimo eziphezulu zekhanda ezinokulahlekelwa okuncane kwamandla.

Izinzuzo Amaphampu Avundlile

Amaphampu e-multistage avundlile aziwa ngokuthembeka kwawo kanye nokuwanakekela kalula. Isisekelo sazo esibanzi, esizinzile sibenza bangakwazi ukubhekana nezinkinga ezihlobene nokusabalalisa isisindo, okuwukukhathazeka okuvamile ngamaphampu aqondile. Ukuklanywa kwamaphampu avundlile futhi kusiza ukufinyelela kalula ezingxenyeni zokuhlola, ukunakekelwa, nokulungiswa, ukunciphisa isikhathi sokuphumula kanye nezindleko zokusebenza.

Mayelana nokusebenza, amaphampu avundlile asebenza kahle kakhulu ekuphatheni amazinga okugeleza aphezulu, okuwenza alungele ukusetshenziswa ezindaweni zezimboni lapho umthamo omkhulu woketshezi udinga ukuthuthwa ebangeni elifushane noma elimaphakathi.

Izinhlelo zokusebenza zamaphampu aqondile aqhathaniswa ne-Horizontal Multistage

Ukusetshenziswa Okukahle kwamaphampu e-Vertical Multistage

Amaphampu e-multistage aqondile asetshenziswa kakhulu ezinhlelweni lapho isikhala siyi-premium kanye nokusebenza kwekhanda eliphezulu kuyadingeka. Zilungele ukusetshenziswa ezindaweni ezijulile zomthombo, lapho iphampu kufanele iphakamise uketshezi kusukela ekujuleni okubalulekile, njengasezinhlelweni zokuphakela amanzi, ukuchelela, nezindawo zokuhlanza amanzi angcolile. Ukwengeza, amaphampu aqondile avame ukusetshenziswa ezinhlelweni lapho iphampu ibekwe ngaphakathi kwezikhala eziqondile ezivaliwe, njengamathangi namashafti.

Ukusetshenziswa Okufanelekile kwamaphampu e-Horizontal Multistage

Amaphampu e-multistage avundlile ngokuvamile asetshenziswa ezinhlelweni ezibandakanya ukugeleza okuphezulu, okumaphakathi ukuya kumasistimu okucindezela okuphezulu. Zilungele ukusetshenziswa ezinhlelweni ezinkulu zezimboni, njengokucutshungulwa kwamakhemikhali, izinhlelo zokuvikela umlilo, kanye nokusatshalaliswa kwamanzi ngezinga elikhulu. Lawa maphampu alungele ukusetshenziswa lapho ukulungiswa kalula kanye nomklamo ozinzile, ofinyelelekayo kuwukucatshangelwa okubalulekile.

Isikhathi sokuthumela: Feb-28-2025

sales@tkflow.com

sales@tkflow.com