Ukugcina i-valve yokuphuma ivaliwe ngesikhathiAmaphampu we-Centrifugalukusebenza kwethula izingozi eziningi zobuchwepheshe.

Ukuguqulwa kwamandla okungalawuleki nokungalingani kwe-thermodynamic

- 1.1 Ngaphansi kwesimo esivaliwe sokukhuphuka kwezinga lokushisa eliphakathi nendawo, cishe wonke amandla okufakwayo aguqulwa abe amandla okushisa. I-medium ayikwazi ukususa ukushisa, okwenza izinga lokushisa ekamelweni lepompo likhuphuke kakhulu. Ukusebenza okuqhubekayo kuzodala ukuhwamuka kwe-medium, kusheshise i-carbonization yezinto zokuvala

1.2 Ukwehluleka kwesistimu yokuvalwa kwendawo enezinga lokushisa eliphezulu kanye nokuhwamuka kwe-medium, uphawu lukamshini oluncike ekugcotshweni nasekupholiseni okuphakathi kuzoholela ekuhlulekeni kokushisa ngokweqile - uphawu olusebenza ngomshini luyoba nokungqubuzana okomile futhi ubuso be-seal buyoshiswa.

Ukucindezeleka kwemishini okungavamile

- 2.1 Ukweqa kwamandla e-axial Amandla e-axial yevalvu yokuvala ngokuvamile izikhathi ezingu-1.5-5 kunezimo zokusebenza ezivamile, futhi umthwalo othwala i-thrust ungase ufinyelele noma udlule umkhawulo wokuthwala, okuholela ekuqhekekeni kwekheji elithwalayo noma ukuguqulwa kwekheji.

2.2 Ukulimala kokudlidliza nokukhathala Umehluko ekwandiseni okushisayo okubangelwa ukushisa okuphezulu kuholela ekushintshashintsheni kokushisa noma ukucindezeleka kokushisa, igebe elingavamile phakathi kwe-impeller nendlu yepompo, kanye nomthelela womthwalo we-hydraulic ongenakulinganisela, obangela ukuba ibhalansi eguquguqukayo ye-rotor yonakaliswe, ukudlidliza kwanda, futhi izingxenye zilimale.

I-Cavitation kanye nomonakalo wezinto ezibonakalayo

3.1 Isibonelelo se-NPSH siguqule ukuhwamuka okuphakathi [yenza i-cavitation allowance (NPSHa) yedivayisi ibe phansi kune-NPSHr edingekayo yepompo], ukwakha amabhamuza, futhi igagasi lokushaqeka elikhiqizwe ukuwa kwamabhamuza lingafinyelela ku-690MPa, okuholela ekuqhumeni nokuchitheka kwezinyosi komgijimi we-impeller.

3.2 Ukuwohloka kwesakhiwo se-metallographic Kuma-impeller ensimbi engenasici ye-austenitic, ukuzwela kungase kwenzeke emazingeni okushisa asendaweni aphezulu, futhi izinga lokugqwala kwe-intergranular lizokhuphuka futhi amandla okubamba azokwehla. Kuma-carbon steel impellers, izinkinga emazingeni okushisa aphezulu zibaluleke kakhulu, njenge-high-temperature oxidation kanye ne-decarburization, okuholela ekunciphiseni kwamandla angaphezulu kanye nezinqubomgomo ezijwayelekile; Uma iqukethe ukungcola okufana nesulfure ne-phosphorus, kulula ukuhlukanisa emingceleni yokusanhlamvu emazingeni okushisa aphezulu, okubangela ukushisa okushisayo nokuqhekeka kalula ngesikhathi sokusebenza; Ngaphansi kwezinga lokushisa eliphakeme lesikhathi eside, i-carbon steel inokumelana nokukhuphuka okuncane, futhi izinga lokushisa eliphezulu lasendaweni lingasheshisa ukuwohloka kwe-creep, okuzogcina kuholele ekuqhekekeni kwe-impeller noma ekuhlulekeni kokukhathala.

Ukuphepha kwesistimu kanye nezingozi zezomnotho

4.1 Ingcindezi yokucindezela kwegobolondo elithwala ingcindezi yeqa umkhawulo futhi ukusebenza kwevalvu yokuvala kwenza ukucindezela kokuphuma kwepompo kufinyelele ku-120-150% yenani elilinganiselwe, futhi kunengozi yokudabula ukucindezela okuhleliwe kwe-valve yokuphepha, okungase kubangele ukukhipha ingcindezi noma ukuqhekeka kwe-weld yepayipi.

4.2 Izindleko zokusetshenziswa kwamandla kanye nokugcinwa kwezindleko zokunakekelwa kwe-Valve ukuvala shaqa "isimo sokubulala" samaphampu we-centrifugal, okwandisa kakhulu ukusetshenziswa kwamandla esikhathini esifushane, futhi ukusebenza kwesikhathi eside kuzoholela ekulimaleni okulimazayo kwemishini, futhi izindleko zokulondoloza ezibanzi zingase zikhuphuke izikhathi ezingu-3-10.

Ukuwohloka kwezimo zokusebenza zemidiya ekhethekile

Kumithombo yezindaba eguquguqukayo (isb, i-LPG), ukusebenza kwe-valve evaliwe kuzosheshisa ukuhwamuka kwesigaba se-liquid, futhi ukugeleza kwe-gas-liquid kwezigaba ezimbili ekamelweni lepompo kuzodala izinguquko ezingazelelwe zokugeleza, okuholela ekugubheni ngezikhathi ezithile kwamandla e-axial kanye nokusheshisa ukuguga kwezingxenye.

Ulwazi lwemboni kanye nezidingo ezijwayelekile

6.1 Okuhlangenwe nakho kwasemboniniNgokokuhlangenwe nakho kwangempela kwesicelo sobunjiniyela, umkhawulo wesikhathi sokusebenza we-valve yepompo ye-centrifugal ngeke udlule amaminithi angu-2, futhi ngokuvamile ukhawulelwe kuminithi elingu-1. Kutuswa ukusetha isistimu yokulawula ukukhiya ukuze uqalise ngokuzenzakalelayo uhlelo lokuvikela ukuvala shaqa lapho ivalvu yokuphuma ivalwa futhi kunezikhathi ezengeziwe.

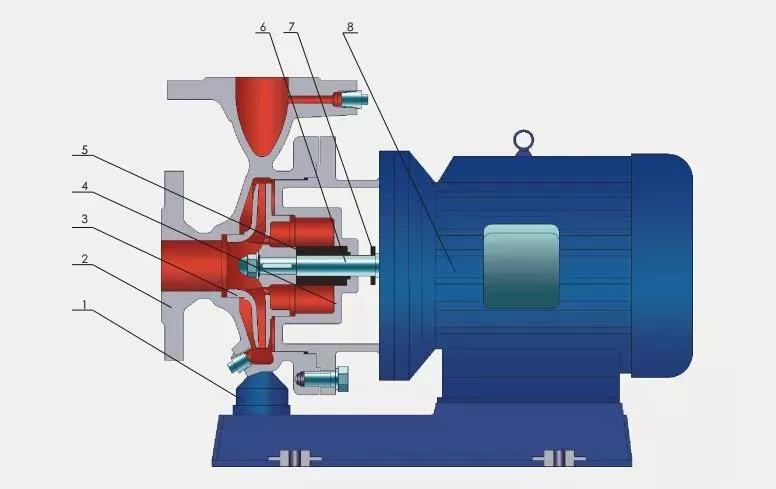

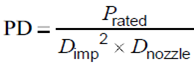

6.2 Ukucaciswa okujwayelekile kudinga ukuthi izinga le-API 610 12th Edition lisho ukuthi amanye amaphampu anamandla aphezulu, agiyelwe ngokuphelele noma esiteji esiningi anokushisa okuphakeme okunyukayo lapho ivalvu yokuphuma ivaliwe, okwenza ukuhlola kungenzeki futhi/noma kungaphephile lapho ivelufa ivaliwe. Ukukhuphuka kwezinga lokushisa kuhlobene eduze nokuminyana kwamandla. I-Power density PD, engalinganiselwa ngokuthi:

I-P ilinganiselwe: Isilinganiso samandla ngesiteji ngasinye uma amanzi ku-hp (noma i-MW)

I-D imp: Isilinganiso se-impeller diameter in. (noma m)

D nozzle: Ububanzi be-flange be-outlet ku-in. (noma m). Ngokumunca kabili, amaphampu esiteji esisodwa, umlomo wombhobho we-D uwububanzi obuyi-inlet flange.

Inani elibalulekile elijwayelekile le-PD lingu-0.286 hp/in.3 (13 MW/m3), ngale kwalokho kunconywa ukuthi ungagijimi iphampu nge-valve yokuphuma ivaliwe ngesikhathi sokuhlolwa kokusebenza.

Isikhathi sokuthumela: Jun-04-2025

sales@tkflow.com

sales@tkflow.com