I-Common Pumping Liquids

Amanzi ahlanzekile

Ukuletha wonke amajika okuhlola iphampu esisekelweni esifanayo, izici zephampu zisekelwe emanzini acacile kuzinga lokushisa elizungezile (ngokuvamile u-15℃) nokuminyana okungu-1000 kg/m³.

Izinto ezivame kakhulu ezakhiweni zamanzi ahlanzekile konke ukwakhiwa kwensimbi eyinsimbi noma i-cast iron casing efakwe izinto zangaphakathi zethusi, Lapho kuphampulwa amanzi ahlanzekile, noma amanzi achazwa kangcono njengokungathathi hlangothi nge-gravity ethize engu-1 ngaphandle kwezinto eziqinile ezikhona,qeda amaphampu okudonsafuthi evundlileamaphampu e-casing ehlukanisayoasetshenziswa kakhulu. Lapho kudingeka amakhanda okukhipha aphezulu, amaphampu ohlobo lwe-multistage asetshenziswa.

Lapho abaklami benqunyelwe indawo yendlu yephampu, amayunithi aqondile okugeleza okuxubile, i-axial noma amaphampu ohlobo lwe-turbine asetshenziswa.

Amanzi olwandle njengendlela edlayo

Amanzi olwandle anosawoti ophelele ongaba ngu-25 g/ℓ. Cishe u-75% wokuqukethwe kukasawoti yi-sodium chloride NaCl. I-pH-value yamanzi olwandle ivamise ukuba phakathi kuka-7,5 no-8,3. Ngokulingana nomkhathi, okuqukethwe komoyampilo ku-15℃ cishe ku-8 mg/ℓ.

Amanzi olwandle aphelile

Kwezinye izimo, amanzi olwandle akhishwa ngamakhemikhali noma ngokwe-physic-ally. Ngenxa yalokhu, ulaka luyancipha kakhulu. Endabeni ye-chemical degasification, kufanele kuqashelwe ukuthi ukukhipha umoya kuthatha isikhathi. Ngakho-ke, kubaluleke kakhulu ukuthi umsebenzi wokukhipha umoya, okungukuthi ukususwa komoya-mpilo, kuqedwe ngokugcwele ngaphambi kokuba amanzi olwandle angene empompini.

Kufanele kuqashelwe ekusebenzeni-ukungena umoya kungenzeka ngokungena komoya. Ngisho noma ama-inrushes anesikhathi esilinganiselwe, ukulimala kwezinto kungase kwenzeke ngokushesha ngaphansi kwezimo ezithile uma ukuba khona komoya-mpilo kungacatshangwa lapho kukhethwa izinto. Uma ukungena komoyampilo kungeke kukhishwe ngesikhathi sokusebenza kwepompo, kufanele kucatshangwe ukuthi amanzi olwandle anomoya-mpilo.

Amanzi anosawoti

Igama elithi 'amanzi anosawoti' lisho amanzi ahlanzekile angcoliswe kakhulu amanzi olwandle. Mayelana nokukhethwa kwempahla, iziqondiso ezifanayo ziyasebenza ekuthuthweni kwamanzi anebrackish njengamanzi olwandle. Ngaphezu kwalokho, amanzi anosawoti ngokuvamile aqukethe i-ammonia kanye/noma i-hydrogen sulphide. Ngisho nokuqukethwe okuphansi kwe-hydrogen sulphide, okungukuthi endaweni yama-milligrams ambalwa ilitha, kubangela ukwanda okuphawulekayo kolaka.

Amanzi olwandle avela emithonjeni engaphansi komhlaba

Amanzi anosawoti aphuma emithonjeni engaphansi komhlaba avamise ukuba nosawoti omningi kunamanzi olwandle, ngokuvamile acishe abe ngama-30%, okusho ukuthi angaphansi komkhawulo wokuncibilika. Nalapha futhi, usawoti ovamile uyisici esiyinhloko. Inani le-pH ngokuvamile liphansi ngokuqhathaniswa (lehle lifinyelele cishe ku-4), okusho ukuthi amanzi ane-asidi. Nakuba okuqukethwe komoyampilo kuphansi kakhulu noma kungabikho nhlobo, okuqukethwe kwe-H₂S kungase kube amamiligremu angamakhulu ambalwa ilitha.

Izixazululo ezinjalo zikasawoti ezine-asidi eziqukethe i-H₂S zigqwala kakhulu futhi zidinga izinto ezikhethekile.

Njengomphumela wokuqukethwe kukasawoti omningi futhi kuye ngezimo zokusebenza, umuntu kufanele alindele izinga elithile lemvula kasawoti. Ezimweni ezinjalo, izinyathelo ezifanele zokuphikisa kufanele zithathwe mayelana nomklamo, ukusebenza kanye nokukhetha impahla.

Ukugqwala emanzini olwandle

Izinto ezisetshenziswayo azibonisi nje ukumelana nokugqwala okuphezulu ngokwanele, kodwa futhi nokugqwala kwendawo ikakhulukazi imigodi nokugqwala kwemifantu. Izimo ezinjalo zokugqwala zitholwa ikakhulukazi ngama-alloys e-ferro azenzelayo (izinsimbi ezingenasici). Okubizwa ngamaphampu 'okubekwe eceleni', asebenza kuphela ngezikhathi ezithile, afaka engcupheni yokugqwala kokuma; ukukhukhula ngamanzi ahlanzekile ngaphambi kwesikhathi sokuvala noma ukuqala ngezikhathi ezithile kuthathwa njengenzuzo.

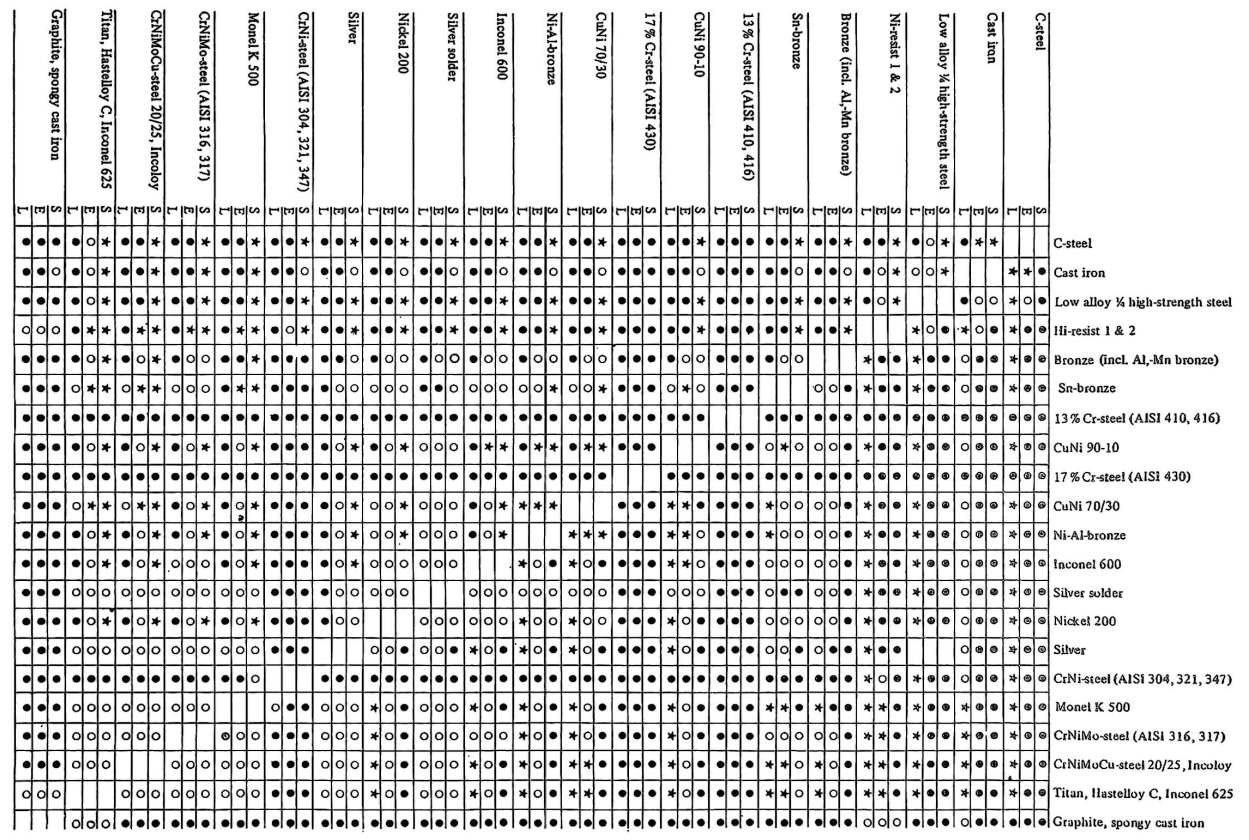

Okuhlukahlukeneiphampu yamanzi olwandleizingxenye kufanele zenziwe ngezinto zohlobo olufanayo ukuze kuvinjelwe ukugqwala kwe-galvanic. Umehluko ongaba khona phakathi kwezinto ezingazodwana kufanele ube phansi ngangokunokwenzeka. Kodwa-ke, uma izinto ezingafani kufanele zisetshenziswe ngenxa yezizathu zokuklama, indawo engaphezulu yensimbi engahlonipheki kangako ethintana namanzi kufanele ibe nkulu uma iqhathaniswa naleyo yensimbi ehloniphekile. Umfanekiso wesi-5 unikeza ulwazi ngengozi yokugqwala kwe-galvanic lapho kuhlanganiswa izinto zohlobo oluhlukile.

Isivinini esiphezulu singaholela ekugugulekeni kwenhlabathi. Imiphumela iba mibi kakhulu, lapho i-medium iba nolaka, futhi inyuka isivinini sayo. Nakuba izinga lokugeleza lithinta ukuziphatha kwezinsimbi ezingagqwali nama-alloys e-nickel ngezinga elincane kuphela, indawo iyahlehliswa lapho kubandakanyeka izinto ezisansimbi ezingaxutshiwe namaalloyi ethusi. Umfanekiso wesi-6 unikeza ulwazi lwekhwalithi ngomthelela wamazinga okugeleza. Kumelwe kucatshangelwe ngalokho ukuthi ingabe isisetshenziswa siqukethe umoya-mpilo noma i-H₂S. Inani elikhulu le-H₂S livame ukungabandakanyi ukuba khona komoya-mpilo; ezimweni ezinjalo, okuphakathi kune-asidi kancane, kuze kufike ku-pH engu-4.

Ukuziphatha kwezinto ezibonakalayo

Ithebula 1 lenza izincomo zezinto zokupompa noma izinhlanganisela zazo. Ngaphandle uma kushiwo ngenye indlela, ulwazi olulandelayo lusebenza emanzini olwandle ngaphandle kokuqukethwe kwe-H₂S.

Insimbi engafakwanga nensimbi

Insimbi engahlanganisiwe ayifaneleki emanzini olwandle, ngaphandle uma ihlinzekwa ngengubo yokuzivikela efanelekile. I-cast iron izosetshenziselwa kuphela isivinini esiphansi (okungenzeka kuma-casings); kulokhu kufanele kusetshenziswe ukuvikelwa okujwayelekile kwe-cathodic kwabanye abangaphakathi.

I-Austenitic Ni-castings

I-Ni-Resist 1 ne-2 ifaneleka kuphela isivinini esiphakathi (kufika ku-20 m/s).

I-Galvanic Corrosion Emanzini Olwandle Ku-5-30℃

Isikhathi sokuthumela: Mar-11-2025

sales@tkflow.com

sales@tkflow.com