Ukulinganisa amandla e-axial kumaphampu e-centrifugal amaningi kuwubuchwepheshe obubalulekile bokuqinisekisa ukusebenza okuzinzile. Ngenxa yokuhlelwa kochungechunge lwama-impellers, amandla e-axial aqoqana kakhulu (kufika kumathani amaningana). Uma kungalinganisi kahle, lokhu kungaholela ekuthwaleni umthwalo omningi, ukulimala kophawu, noma ngisho nokuhluleka kwemishini. Ngezansi kunezindlela ezivamile zokulinganisa amandla e-axial, kanye nezimiso zazo, izinzuzo, kanye nokubi.

1.I-Symmetrical Impeller Arrangement (I-Back-to-Back / Ubuso-nobuso)

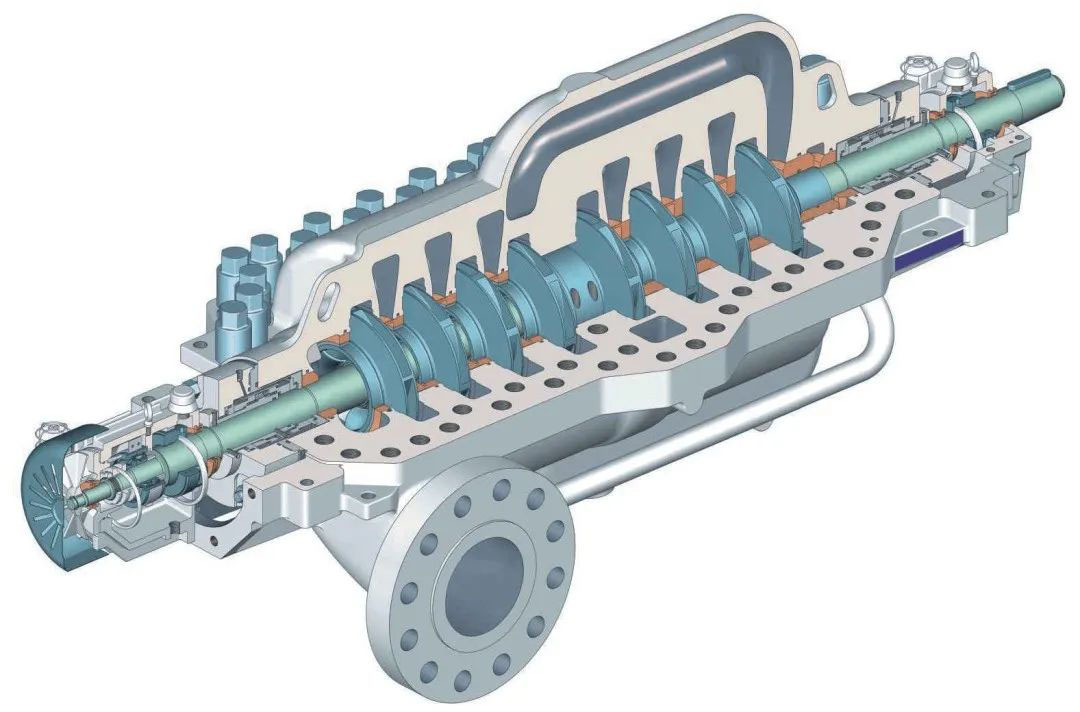

Ekwakhiweni kwedivaysi ye-axial force balance yepompo yesimanje ye-centrifugal, isiteji se-impeller ngokuvamile sikhethwa njengenombolo elinganayo, ngoba lapho isigaba se-impeller siyinombolo elinganayo, indlela yokusabalalisa i-impeller symmetrical ingasetshenziswa ukulinganisa amandla e-axial wemishini, futhi amandla e-axial akhiqizwa i-impeller esabalaliswe ngokulinganayo kwinqubo ye-magnide izobonisa isiqondiso esiphambene nenqubo yokusebenza. isimo sokulingana ezingeni le-macroscopic. Enqubweni yokuklama, kufanele kuqashelwe ukuthi usayizi wokuvala uphawu ngaphambi kokungena kwe-impeller reverse kuyahambisana nobubanzi be-impeller ukuqinisekisa ukuvala kahle.

●Isimiso: Ama-impeller aseduze ahlelwa ngezindlela eziphambene ukuze amandla awo a-axial akhansele ngaphandle.

●Ukubuyela emuva: Amasethi amabili wama-impeller afakwe ngokulinganayo azungeze indawo emaphakathi ye-pump shaft.

●Ubuso nobuso: Ama-impeller ahlelwa abheke ngaphakathi noma ngaphandle ngokucushwa kwesibuko.

●Izinzuzo: Awekho amadivaysi engeziwe adingekayo; isakhiwo esilula; ukusebenza kahle kokulinganisa okuphezulu (ngaphezu kwama-90%).

●Ukubi: Umklamo wezindlu wephampu oyinkimbinkimbi; ukusebenza kahle kwendlela yokugeleza; kusebenza kuphela kumaphampu anenani elilinganayo lezigaba.

●Izinhlelo zokusebenza: Amaphampu okuphakelayo kubhayela wokucindezela okuphezulu, amaphampu e-petrochemical multistage.

2. Isigubhu sokulinganisa

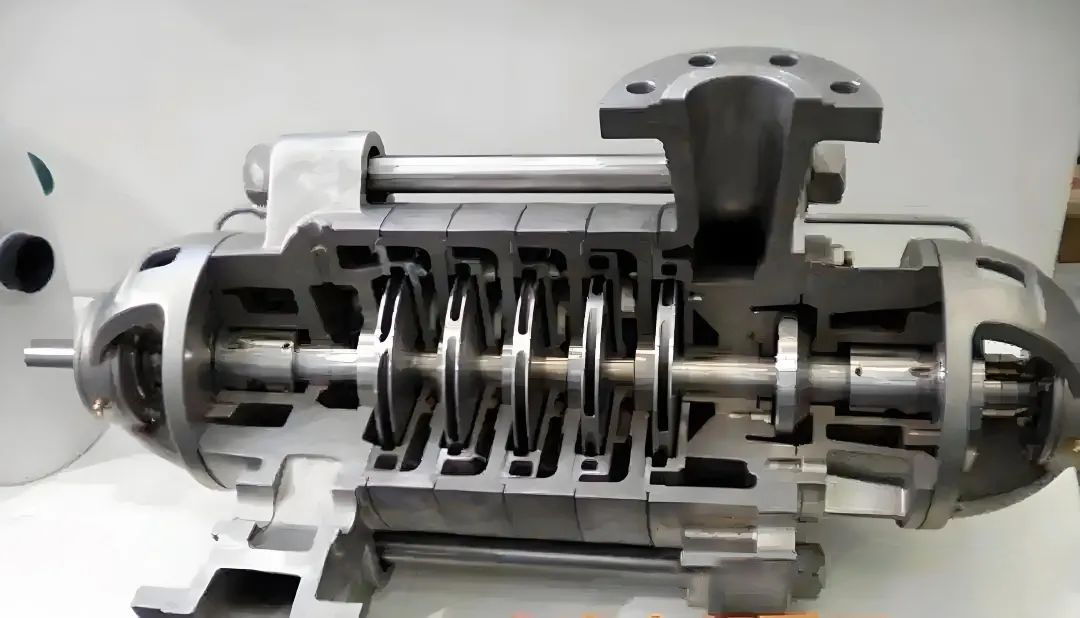

Isakhiwo sesigubhu sebhalansi (esaziwa nangokuthi i-balance piston) asinayo imvume yokugijima ye-axial eqinile, engakhokhela iningi le-axial thrust, kodwa hhayi yonke i-axial thrust, futhi ayikho isinxephezelo esengeziwe lapho uhamba endaweni ye-axial, futhi ama-thrust bearings ayadingeka ngokuvamile. Lo mklamo uzoba nokujikeleza kabusha kwangaphakathi okuphezulu (ukuvuza kwangaphakathi) kodwa uyakwazi ukubekezelela ukuqalisa, ukuvala shaqa, nezinye izimo zesikhashana.

●Isimiso: Isigubhu esiyi-cylindrical sifakwe ngemva kwe-impeller yesigaba sokugcina. Uketshezi olunomfutho ophezulu luvuza ngegebe eliphakathi kwesigubhu kanye ne-casing ekamelweni elinomfutho ophansi, okukhiqiza amandla aphikisayo.

● Aizinzuzo: Amandla okulinganisa aqinile, afanele ukucindezela okuphezulu, amaphampu esiteji esiningi (isb., izigaba eziyi-10+).

●Ukubi: Ukulahlekelwa kokuvuza (~ 3-5% wezinga lokugeleza), ukunciphisa ukusebenza kahle. Idinga amapayipi okulinganisa engeziwe noma amasistimu okubuyisela kabusha, okwandisa ubunkimbinkimbi bokulungisa.

●Izinhlelo zokusebenza: Amaphampu amakhulu esiteji esikhulukazi (isb., amaphayiphi ahamba amabanga amade).

3.I-Balanceing Disk

Njengendlela evamile yokuklama inqubo yokuklama idivayisi ye-axial force balance yepompo yesimanje ye-multistage centrifugal, indlela ye-balance disc ingalungiswa ngokulinganisela ngokuvumelana nesidingo sokukhiqiza, futhi amandla okulinganisa akhiqizwa ikakhulukazi phakathi kwe-cross-section phakathi kwe-radial clearance kanye ne-axial clearance ye-disk, kanti enye ingxenye ikhiqizwa ngokuyinhloko yi-axial balance disc kanye nalezi zingxenye ezimbili ze-balance balance kanye nesigaba sokudlala se-balance. ukulinganisa amandla e-axial. Uma kuqhathaniswa nezinye izindlela, inzuzo yendlela ye-balance plate ukuthi ububanzi be-balance plate bukhulu futhi ukuzwela kuphakeme, okuthuthukisa ngokuphumelelayo ukuzinza kokusebenza kwedivayisi yemishini. Kodwa-ke, ngenxa yemvume encane yokugijima kwe-axial, lo mklamo usengozini yokugqoka nokulimala ngaphansi kwezimo zesikhashana.

●Isimiso: Idiski ethathekayo ifakwa ngemva kwe-impeller yesigaba sokugcina. Umehluko wengcindezi kuyo yonke idiski ulungisa indawo yayo ukuze imelane namandla e-axial.

●Izinzuzo: Ivumelana ngokuzenzakalelayo nokuhlukahluka kwamandla e-axial; ukunemba kokulinganisa okuphezulu.

●Ukubi: Ukungqubuzana kubangela ukuguga, okudinga ukushintshwa ngezikhathi ezithile. Izwela ukuhlanzeka koketshezi (izinhlayiya zingayiminyanisa idiski).

●Izinhlelo zokusebenza: Amaphampu amanzi ahlanzekile esiteji sakuqala (kancane kancane athathelwa indawo imigqomo yokulinganisa).

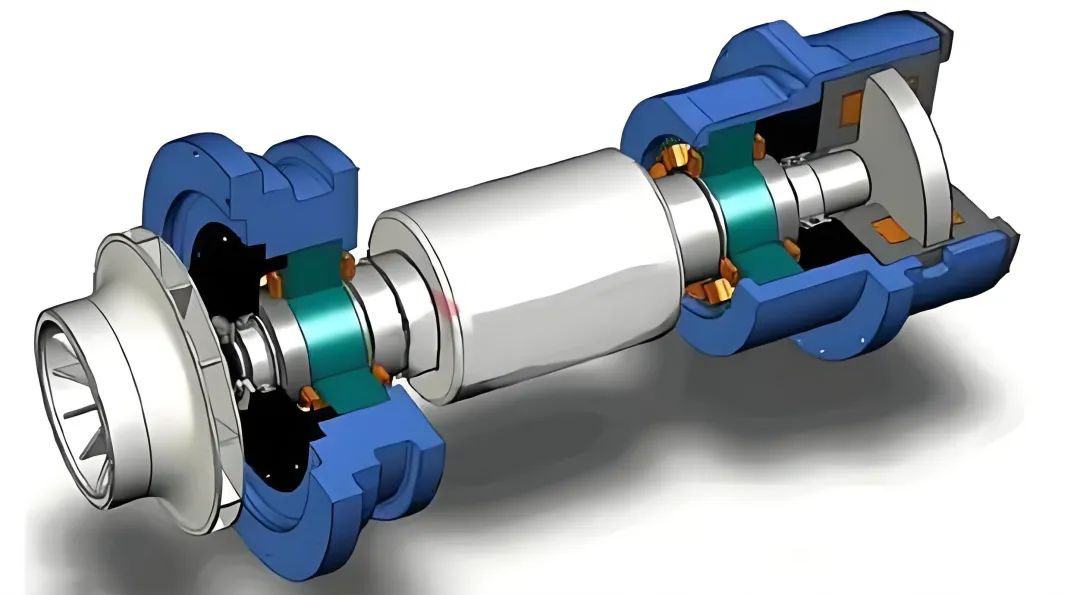

4.Ukulinganisa Isigubhu + Inhlanganisela Yediski

Uma kuqhathaniswa nendlela ye-balance plate, indlela yesigubhu se-balance plate ihlukile ngokuthi usayizi wengxenye yayo ye-throttle bushing inkulu kunosayizi wehabhu le-impeller, kuyilapho i-balance disc idinga usayizi we-throttle bushing ukuze uhambisane nosayizi wehabhu le-impeller. Ngokuvamile, endleleni yokuklama yesigubhu se-balance plate, amandla ebhalansi akhiqizwa i-balance plate alandisa ngaphezu kwengxenye yawo wonke amandla e-axial, futhi inani eliphakeme lingafinyelela ku-90% wengqikithi yamandla e-axial, kanti ezinye izingxenye zihlinzekwa ngokuyinhloko yisigubhu sebhalansi. Ngesikhathi esifanayo, ukukhulisa ngokusesilinganisweni amandla ebhalansi yesigubhu sebhalansi kuzonciphisa ngokufanayo amandla ebhalansi epuleti lebhalansi, futhi ngokufanayo kunciphise usayizi wepuleti lebhalansi, ngaleyo ndlela kunciphise izinga lokuguga lepuleti lebhalansi, kuthuthukiswe impilo yesevisi yezingxenye zemishini, nokuqinisekisa ukusebenza okuvamile kwephampu ye-multistage centrifugal.

●Isimiso: Isigubhu siphatha amandla amaningi e-axial, kuyilapho idiski ishuna kahle amandla ayinsalela.

●Izinzuzo: Ihlanganisa ukuzinza nokuzivumelanisa nezimo, ezifanele izimo zokusebenza eziguquguqukayo.

●Ukubi: Isakhiwo esiyinkimbinkimbi; izindleko eziphezulu.

●Izinhlelo zokusebenza: Amaphampu ezimboni asebenza kahle kakhulu (isb., amaphampu okupholisa amandla enuzi).

5. Ama-Thrust Bearings (I-Axiliary Balancing)

●Isimiso: Ama-angular contact ball bearings noma ama-Kingsbury bearings amunca amandla asele e-axial.

●Izinzuzo: Isipele esithembekile kwezinye izindlela zokulinganisa.

●Ukubi: Idinga ukugcotshwa njalo; isikhathi sokuphila esifushane ngaphansi kwemithwalo ephezulu ye-axial.

●Izinhlelo zokusebenza: Amaphampu we-multistage amancane kuya kwaphakathi noma amaphampu anesivinini esikhulu.

6. I-Double-Suction Impeller Design

●Isimiso: I-impeller edonsa kabili isetshenziswa esigabeni sokuqala noma esimaphakathi, ibhalansisa amandla e-axial ngokusebenzisa ukungena kwezinhlangothi ezimbili.

●Izinzuzo: Ukulinganisa okuphumelelayo ngenkathi kuthuthukisa ukusebenza kwe-cavitation.

●Ukubi: Ibhalansila kuphela amandla e-axial esiteji esisodwa; ezinye izindlela ziyadingeka kumaphampu ezigaba eziningi.

7. Izimbobo Zebhalansi Ye-Hydraulic (Izimbobo Ze-Impeller Backplate)

●Isimiso: Izimbobo zibhojwa ku-backplate ye-impeller, okuvumela uketshezi olunomfutho ophezulu ukuba luphinde lujikeleze endaweni yokucindezela okuphansi, kunciphisa amandla e-axial.

●Izinzuzo: Ilula futhi inezindleko eziphansi.

●Ukubi: Yehlisa ukusebenza kwephampu (~2–4%).Ifanele kuphela izicelo eziphansi ze-axial force; ngokuvamile kudinga ama-thrust bearings engeziwe.

Ukuqhathaniswa kwe-Axial Force Bancing Izindlela

| Indlela | Ukusebenza kahle | Inkimbinkimbi | Izindleko Zokulungisa | Izicelo Ezijwayelekile |

| I-Symmetrical Impellers | ★★★★★ | ★★★ | ★★ | Amaphampu anomfutho ophezulu wesiteji |

| Isigubhu sokulinganisa | ★★★★ | ★★★★ | ★★★ | Amaphampu asezingeni eliphezulu |

| I-Balanceing Disk | ★★★ | ★★★★ | ★★★★ | Uketshezi oluhlanzekile, imithwalo eguquguqukayo |

| I-Drum + Disk Combo | ★★★★★ | ★★★★★ | ★★★★ | Izimo ezimbi kakhulu (inuzi, impi) |

| I-Trust Bearings | ★★ | ★★ | ★★★ | Ukulinganisa kwe-axial force eyinsalela |

| I-Double-Suction Impeller | ★★★★ | ★★★ | ★★ | Isiteji sokuqala noma esiphakathi |

| Ibhalansi Izimbobo | ★★ | ★ | ★ | Amaphampu amancane anengcindezi ephansi |

Isikhathi sokuthumela: Mar-29-2025

sales@tkflow.com

sales@tkflow.com