Amaphampu e-Centrifugal aphakathi kwemishini esetshenziswa kakhulu ukuthutha uketshezi ezimbonini ezihlukahlukene, kusukela ekuhlanzeni amanzi nakwezolimo kuya kuwoyela negesi kanye nokukhiqiza. Lawa maphampu asebenza ngomgomo oqondile kodwa onamandla:usebenzisa amandla aphakathi nendawo ukuthutha uketshezi ngendlela efanele futhi enokwethenjelwa. Kodwa zisebenza kanjani ngempela?

Ukuqonda Okuyisisekelo kwamaphampu aseCentrifugal

Iphampu ye-centrifugal iwuhlobo lwephampu eguquguqukayo esebenzisa amandla e-kinetic we-impeller ezungezayo ukukhulisa isivinini soketshezi. Lesi sivinini sibe sesiguqulwa sibe amandla okucindezela, okwenza uketshezi luhanjiswe ngohlelo lwamapayipi.

Amaphampu e-Centrifugal adlala indima enkulu ekudluliselweni koketshezi. Iphampu ye-Centrifugal yakhiwe izingxenye eziningi, ezingahlukaniswa cishe zibe izinhlobo ezintathu ngokuya ngesimo sokusebenza sengxenye ngayinye ngesikhathi sokusebenza:

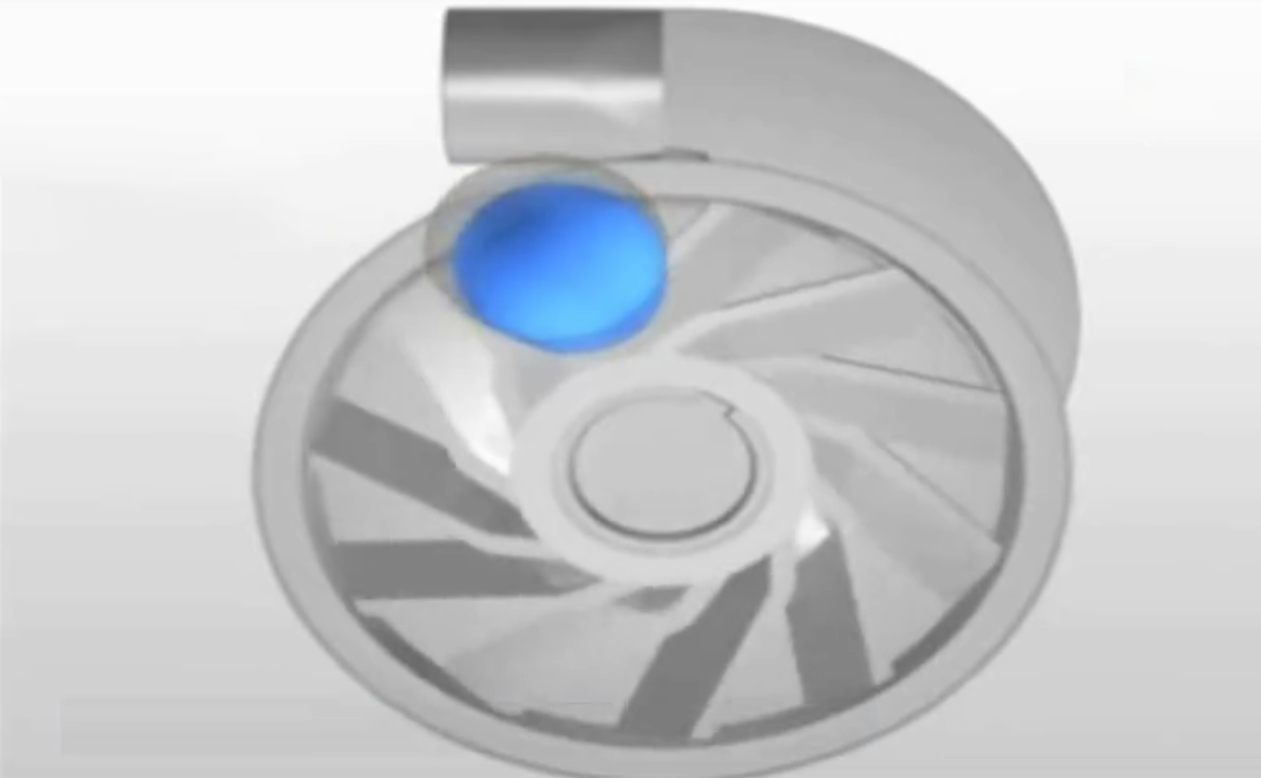

I-impelleringxenye eyinhloko yepompo, engenza amanzi athole amandla e-kinetic futhi akhiqize ukugeleza.

Iphampu shaftisetshenziselwa ukuzungezisa i-impeller.

Isikhwama sepompoyakhiwe izingxenye eziningana, futhi igumbi layo elingaphakathi lakha i-impeller chamber, i-suction chamber kanye ne-pressurized chamber.

Iqhaza Le-Centrifugal Force

Amaphampu e-Centrifugal asebenza ngokusebenzisa amandla amaphakathi akhiqizwa amanzi akhiqizwa ukuzungezisa kwe-impeller. Ngaphambi kokuqala iphampu eyi-centrifugal, isikhwama sepompo kanye negumbi lokudonsa kufanele ligcwaliswe ngamanzi, bese umshini kufanele uqalwe ukwenza i-pump shaft ishayele i-impeller namanzi ukwenza ukunyakaza kwe-rotary ngesivinini esikhulu. Ngaphansi kwesenzo samandla e-centrifugal, amanzi aphonswa emaphethelweni angaphandle e-impeller futhi ageleza emgqeni wamanzi ocindezelwe wepompo ngokusebenzisa umzila wokugeleza we-snyl pump casing.

Maphakathi nendawo ye-impeller yepompo yamanzi, amanzi ethangini lokumunca acindezelwa ku-casing yepompo ngaphansi kwesenzo sokucindezela komkhathi ngoba amanzi aphonswa ngaphandle ngaphansi kwesenzo samandla e-centrifugal ukuze enze i-vacuum. I-impeller ijikeleza ngokuqhubekayo ukuze amanzi aqhubeke egeleza futhi ephuma ngaphansi kwesenzo se-impeller, esifeza injongo yokuthutha amanzi.

Nansi indlela inqubo eyenzekayo:

Ukungena Kwamanzi: Uketshezi lungena empompini ngembobo yokudonsa bese lugelezela phakathi nendawo ye-impeller, eyaziwa ngokuthi iso.

Ukudlulisa Amandla: Njengoba i-impeller spins (inikwe amandla yinjini), isheshisa uketshezi oluya ngaphandle ngenxa yamandla amaphakathi. Lokhu kunyakaza kwangaphandle kwandisa isivinini soketshezi.

Ukuguqulela Kungcindezi: Uma uketshezi lwesivinini esiphezulu lushiya i-impeller, lungena emgodini wepompo, lapho isivinini sawo sincishiswa. Lokhu kwehla kwesivinini kubangela amandla e-kinetic ukuthi aguqulwe abe amandla okucindezela.

Ukukhipha Uketshezi: Uketshezi manje olunomfutho luphuma empompini ngembobo yokukhipha, lulungele ukulethwa ngamapayipi ukuya lapho luya khona.

Ukusebenza kahle kanye nezicelo

Amaphampu e-Centrifugal ayigugu ngenxa yawoubulula, ukuqina, nokusebenza kahle. Zikulungele kangcono ukuthutha uketshezi olune-viscosity ephansi njengamanzi, amakhemikhali, namafutha alula. Ngenxa yokwakheka kwawo, angakwazi ukuphatha umthamo omkhulu woketshezi ngomfutho ophansi uma kuqhathaniswa.

Izicelo ezijwayelekile zifaka:

Ukuhlinzekwa kwamanzi kamasipala

Izinhlelo zokunisela

Ukudluliswa koketshezi lwezimboni

Ukupholisa kanye nezinhlelo zokufudumeza

Ukucima umlilo

Isiphetho

Amaphampu e-Centrifugal asebenzisa ngempumelelo amandla we-centrifugal force ukuhambisa uketshezi, aguqule amandla azungezayo abe amandla adonsa kanzima ngobunkimbinkimbi bemishini obuncane. Ikhono labo lokuphatha ukugeleza okuqhubekayo, kuhlanganiswe nokulondolozwa kalula, kubenza babaluleke kakhulu kukho kokubili ukuhweba kanyeimisebenzi yezimboni.

Isikhathi sokuthumela: Apr-21-2025

sales@tkflow.com

sales@tkflow.com