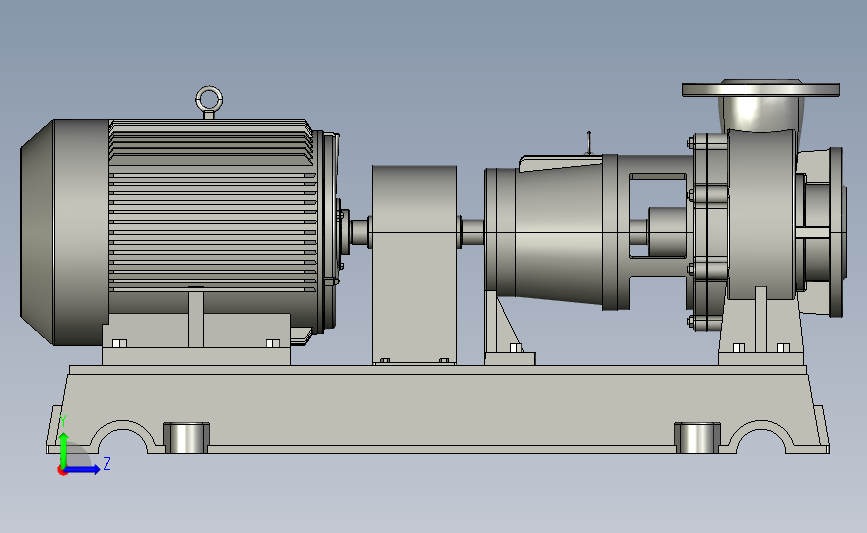

I-Centrifugal Pump Seal Basics

Amaphampu we-Centrifugalasetshenziswa kakhulu ezimbonini ezahlukahlukene, okubandakanya uwoyela negesi, ukucubungula amakhemikhali, ukwelapha amanzi, kanye nokukhiqiza amandla, ukuthutha uketshezi ngendlela efanele. Enye yezingxenye ezibalulekile zephampu ye-centrifugal wuhlelo lokuvala, oluvimbela ukuvuza koketshezi olupompowe futhi luqinisekise ukuthi iphampu isebenza ngokuphepha nangempumelelo. Phakathi kwezinhlobo ezahlukene zezinhlelo zokuvala uphawu, izigxivizo ezimbili ezisebenza ngomshini zivame ukusetshenziswa ezinhlelweni lapho ukuvimbela ukuvuza kubaluleke kakhulu. Kodwa-ke, amazinga okushisa aphezulu angabangela izinselele ezibalulekile ekuthembekeni kwezinhlelo zokuvala uphawu oluphindwe kabili, okungase kuholele ekwenyukeni okuyingozi kokucindezela kanye nokwehluleka okuyinhlekelele.

Izisekelo ze-Centrifugal Pump Seals

Izigxivizo zemishini ziwuhlobo oluvame kakhulu lwesistimu yokuvala esetshenziswa kumaphampu amaphakathi. Aqukethe izingxenye ezimbili eziyinhloko: ubuso bophawu olunganyakazi kanye nobuso obuzungezayo bophawu, obucindezelwa ndawonye ukuze bakhe uphawu oluqinile. Ubuso bophawu ngokuvamile benziwa ngezinto ezihlala isikhathi eside njengekhabhoni, i-ceramic, noma i-silicon carbide, engamelana nezimo ezinzima ngaphakathi kwepompo. Inhloso eyinhloko yophawu ukuvimbela uketshezi olumponliwe ukuthi lungavuzi ngaphandle kwesikhwama sepompo kuyilapho ugcina ukungcola kungangeni ohlelweni.

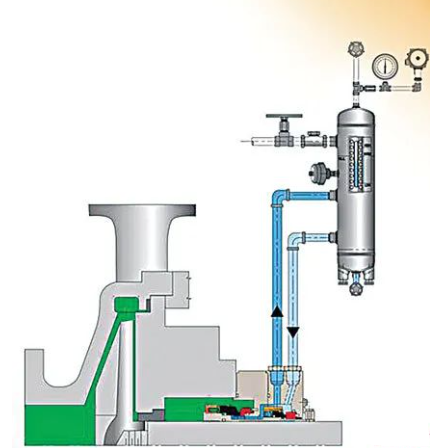

Ezinhlelweni ze-single mechanical seal, isethi eyodwa yobuso be-seal isetshenziselwa ukuqukatha uketshezi. Kodwa-ke, ekusetshenzisweni okubandakanya uketshezi oluyingozi, olunobuthi, noma olunomfutho ophezulu, isistimu yokuvala uphawu eyimishini ekabili ivamise ukusetshenziswa. Izigxivizo eziphindwe kabili zihlanganisa amasethi amabili obuso be-seal obuhlelwe ngokwe-tandem noma ukulungiswa kwe-back-to-back, okunoketshezi oluvimbelayo phakathi kwakho. Lo mklamo unikeza isendlalelo esengeziwe sokuvikela ekuvuzeni futhi sithuthukise ukwethembeka kwesistimu yokuvala uphawu.

I-Double Seal Systems kanye Nezinzuzo Zazo

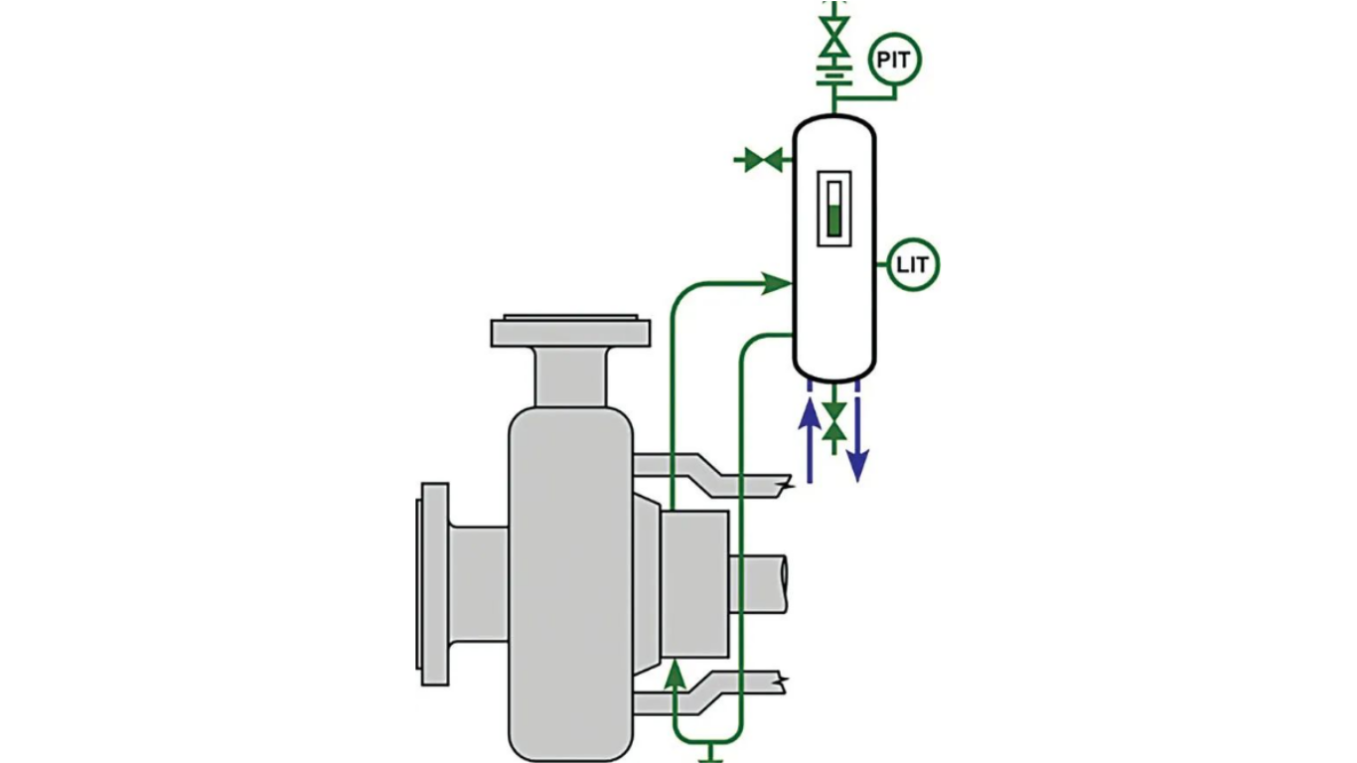

Izigxivizo ezisebenza kabili ezisebenza ngomshini ziwusizo ikakhulukazi ezinhlelweni lapho ukuvimbela ukuvuza kubalulekile. Uketshezi oluvimbelayo phakathi kwamasethi amabili obuso be-seal lusebenza njengesivimbeli, luvimbela uketshezi olumpontshiwe ukuthi lubaleke luye endaweni ezungezile. Ukwengeza, uketshezi oluvimbelayo lusiza ukugcoba nokupholisa ubuso be-seal, ukunciphisa ukuguga nokwelula impilo yezimpawu. Izigxivizo eziphindwe kabili zivame ukusetshenziswa ezinhlelweni ezibandakanya ukucindezela okuphezulu, izinga lokushisa eliphezulu, uketshezi olubolayo, noma uketshezi oluyingozi emvelweni.

Kunezinhlobo ezimbili eziyinhloko zokucushwa kwezigxivizo ezimbili:

I-Tandem Seals: Kulokhu kumisa, uphawu lokuqala lubhekane noketshezi olupompowe, kuyilapho uphawu lwesibili lusebenza njengesipele uma uphawu lokuqala lwehluleka. Uketshezi oluvimbelayo luvamise ukugcinwa ngaphansi kwengcindezi ephansi kunoketshezi olumpontshwayo ukuze kuqinisekiswe ukuthi noma yikuphi ukuvuza kugelezela ngaphakathi kupompo.

I-Back-to-Back Seals: Kulolu hlelo, amasethi amabili obuso be-seal aqondiswe ezinhlangothini eziphambene, uketshezi oluvimbelayo lugcinwa kungcindezi ephakeme kunoketshezi olupompowe. Lokhu kulungiselelwa kuvame ukusetshenziswa ezinhlelweni ezibandakanya uketshezi olushintshashintshayo noma oluyingozi.

Umthelela Wamazinga Okushisa Aphezulu Kumasistimu Ophawu Oluphindwe Kabili

Nakuba amasistimu e-double seal enikeza izinzuzo ezibalulekile, awagonyiwe ezinseleleni ezibangelwa amazinga okushisa aphezulu. Amazinga okushisa aphezulu angavela emithonjeni ehlukahlukene, okuhlanganisa uketshezi olumpontshwa, indawo yokusebenza, noma ukungqubuzana phakathi kobuso bophawu. Lapho amazinga okushisa enyuka, kungase kwenzeke izinkinga ezimbalwa ezifaka engozini ubuqotho besistimu yophawu:

Ukunwetshwa kwe-Thermal:Amazinga okushisa aphezulu abangela ukuba izinto ezisebusweni bophawu nezinye izingxenye zande. Uma ukunwetshwa kwe-thermal kungafani, kungaholela ekuqondeni kabi kobuso be-seal, okuholela ekukhuphukeni kokuvuza noma ukwehluleka kokuvala.

Ingcindezi Eyenyukile ku-Barrier Fluid:Ohlelweni lokuvala uphawu olukabili, uketshezi lokuvimbela lubalulekile ekugcineni ubuqotho bophawu. Kodwa-ke, amazinga okushisa aphezulu angabangela ukwanda kwe-barrier fluid, okuholela ekwenyukeni okuyingozi kokucindezela ngaphakathi kwegumbi le-seal. Uma ingcindezi idlula imikhawulo yokuklama yesistimu yophawu, ingabangela ukuhluleka kwezimpawu, kubangele ukuvuza noma ngisho nomonakalo oyinhlekelele wepompo.

Ukucekelwa phansi kwempahla ye-Seal:Ukuchayeka isikhathi eside emazingeni okushisa aphezulu kungabangela izinto ezisetshenziswa ebusweni bophawu ukuthi ziwohloke. Isibonelo, ama-elastomer asetshenziswa kuma-O-rings noma kuma-gaskets angase aqine noma aqhekeke, kuyilapho ubuso be-carbon noma be-ceramic seal bungase bube bushelelezi. Lokhu konakala kungalimaza ikhono lophawu lokugcina umgoqo oqinile, okuholela ekuvuzeni.

I-vaporization ye-Barrier Fluid:Ezimweni ezimbi kakhulu, amazinga okushisa aphezulu angabangela ukuthi uketshezi oluvimbelayo luhwamuke, ludale amaphakethe egesi ngaphakathi kwegumbi lokuvala uphawu. Lawa maphakethe egesi angaphazamisa ukugcotshwa nokupholiswa kobuso be-seal, okuholela ekwenyukeni kokungqubuzana, ukuguga, kanye nokungasebenzi kahle kophawu.

Ukunciphisa Izingozi Zamazinga Okushisa Aphakeme

Ukuze uvimbele imiphumela emibi yamazinga okushisa aphezulu ezinhlelweni ze-double seal, izinyathelo ezimbalwa zingathathwa:

Ukukhetha Okufanelekile:Ukukhetha izinto zokuvala ezikwazi ukumelana namazinga okushisa aphezulu kubalulekile. Isibonelo, ama-elastomers asezingeni eliphezulu afana ne-fluorocarbon noma i-perfluoroelastomer (FFKM) angasetshenziselwa ama-O-rings, kuyilapho izinto zobumba ezithuthukisiwe noma i-silicon carbide zingasetshenziselwa ubuso be-seal.

Hlola isilinganiso sebhalansi:Ukukhetha uphawu oludizayinelwe ukucindezela okuphezulu koketshezi oluhlukanisayo kuphawu lokuqala.

Amasistimu wokupholisa:Ukufaka amasistimu okupholisa, afana nezishintshisi zokushisa noma amajakhethi okupholisa, kungasiza ukuqeda ukushisa nokugcina izinga lokushisa loketshezi oluvimbelayo ngaphakathi kwemikhawulo ephephile.

Ukulawulwa Kwengcindezi:Ukuqapha nokulawula ukucindezela koketshezi oluvimbelayo kubalulekile ukuvimbela ukwanda komfutho oyingozi. Ama-valve okunciphisa ingcindezi noma amasistimu okulawula ukucindezela angafakwa ukuze kugcinwe uketshezi oluvimbelayo lapho kunengcindezi efanele.

Ukunakekela Okuvamile:Ukuhlolwa njalo nokunakekelwa kwesistimu yezimpawu kungasiza ekuhlonzeni nasekuxazululeni izinkinga ngaphambi kokuba ziholele ekwehlulekeni. Lokhu kuhlanganisa ukubheka izimpawu zokuguga, ukungahambi kahle, noma ukucekelwa phansi kwezinto zokuvala uphawu.

Isiphetho

Iphampu ye-TKFLO centrifugalama-seal, ikakhulukazi ama-double mechanical seal, adlala indima ebalulekile ekuqinisekiseni ukuthi amaphampu asebenza ngendlela ephephile futhi ephumelelayo ekufakweni okufunwayo. Kodwa-ke, amazinga okushisa aphezulu angabangela ubungozi obubalulekile ekuthembekeni kwezinhlelo zokuvala uphawu oluphindwe kabili, okuholela ekwenyukeni kwengcindezi, ukuwohloka kwempahla, kanye nokwehluleka kwezitywina okungenzeka. Ngokuqonda izinto eziyisisekelo ze-centrifugal pump seal nokusebenzisa izinyathelo ezifanele zokunciphisa imithelela yamazinga okushisa aphezulu, opharetha bangathuthukisa ukwethembeka nokuphila isikhathi eside kwezinhlelo zabo zephampu. Ukukhetha impahla efanele, izinhlelo zokupholisa, ukulawula ingcindezi, nokugcinwa njalo kuyizici ezibalulekile zesu eliqinile lokubhekana nezinselele ezibangelwa amazinga okushisa aphezulu ezinhlelweni zokuvala uphawu oluphindwe kabili.

Isikhathi sokuthumela: Mar-17-2025

sales@tkflow.com

sales@tkflow.com