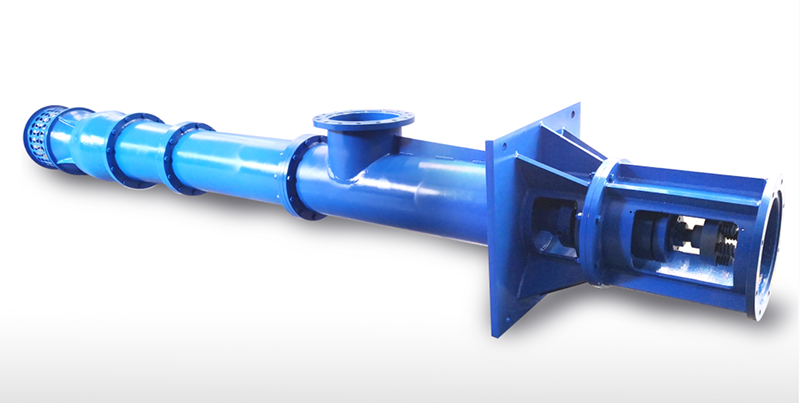

Impahla Yephampu ye-turbine eqondile

Isitsha: Insimbi yokusansimbi, insimbi engagqwali

Umphini: Insimbi engagqwali

I-Impeller: I-cast iron, Bronze noma insimbi engagqwali

Ikhanda elikhiphayo: I-cast iron noma i-carbon steel

Inzuzo yepompo

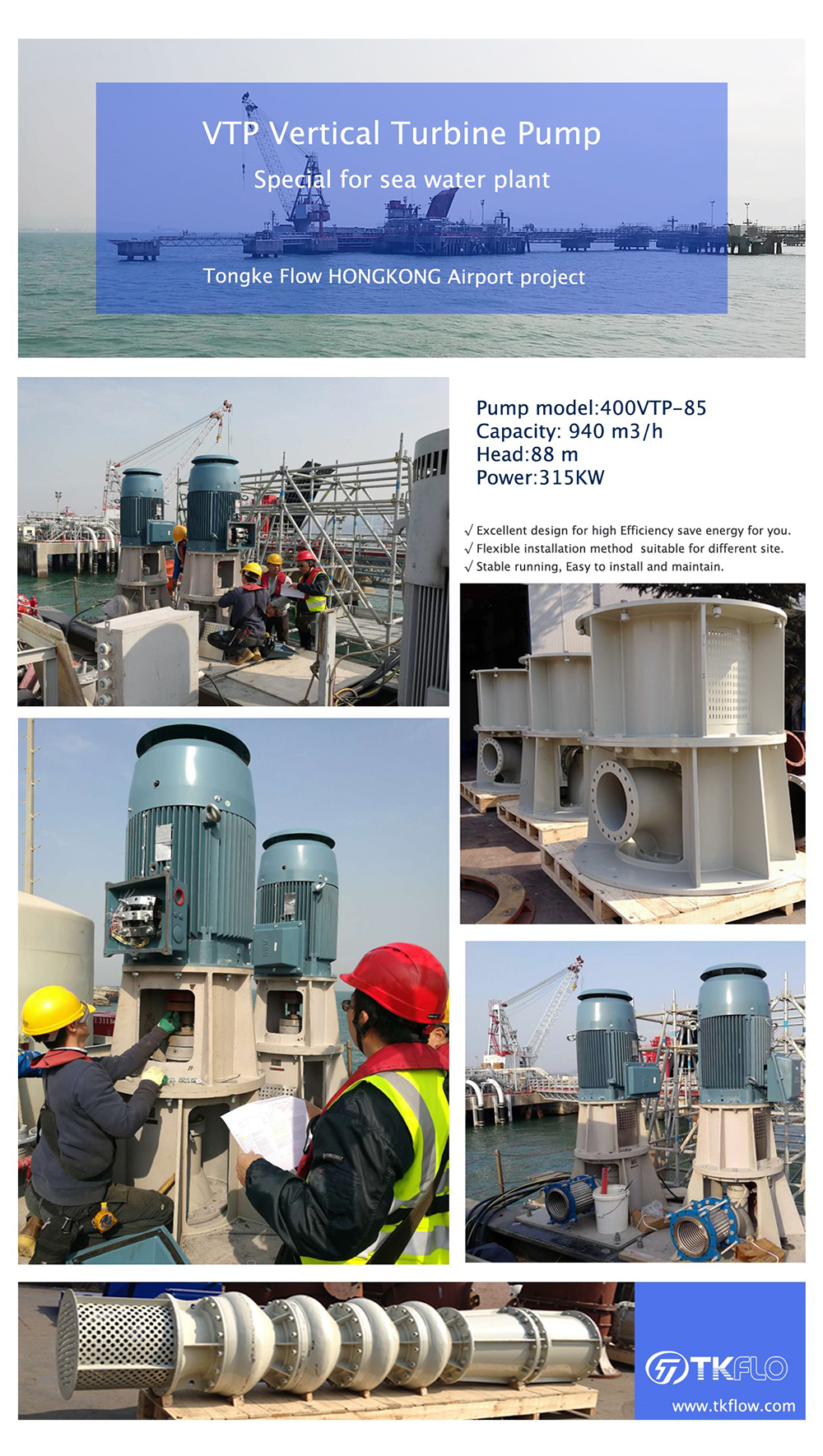

√ Ingxenye eyinhloko yokumelana nokugqwala, ukuzala komkhiqizo odumile, ama-thordon bearings afanele amanzi olwandle.

√ Idizayini enhle kakhulu yokusebenza kahle okuphezulu konga amandla kuwe.

√ Indlela yokufaka eguquguqukayo efanele indawo ehlukile.

√ Ukusebenza okuzinzile, Kulula ukukufaka nokugcina.

1. I-inlet izoba mpo iye phansi futhi i-outlet ivundlile ngenhla noma ngaphansi kwesisekelo.

2. I-impeller yepompo ihlukaniswa ngohlobo oluvalekile kanye nohlobo lokuvula ingxenye, kanye nokulungiswa okuthathu: okungaguquki, okuguquguqukayo okuncane futhi okuguquguqukayo okugcwele. Akudingekile ukugcwalisa amanzi lapho ama-impeller ecwiliswa ngokugcwele oketshezini olupompowe.

3. Ngokusekelwe ku-o Iphampu, lolu hlobo luhambisana ngokungeziwe ne-muff armor tubing futhi ama-impellers enziwe ngezinto ezimelana nokugwazwa, anweba ukusebenza kwepompo.

4. Ukuxhunywa kwe-impeller shaft, i-transmission shaft, ne-motor shaft kusebenzisa amantongomane ahlanganisa i-shaft.

5. Isebenzisa amanzi okugcoba irabha ethwele kanye nokupakisha uphawu.

6. I-motor ngokuvamile isebenzisa uchungechunge olujwayelekile lwe-Y uchungechunge lwe-tri-phase asynchronous motor, noma uhlobo lwe-YLB uhlobo lwe-tri-phase asynchronous motor njengoba iceliwe. Lapho uhlanganisa injini yohlobo lwe-Y, iphampu idizayinelwe ngedivayisi ephikisana nokuhlehla, igwema ngokuphumelelayo ukuhlehla kwepompo.

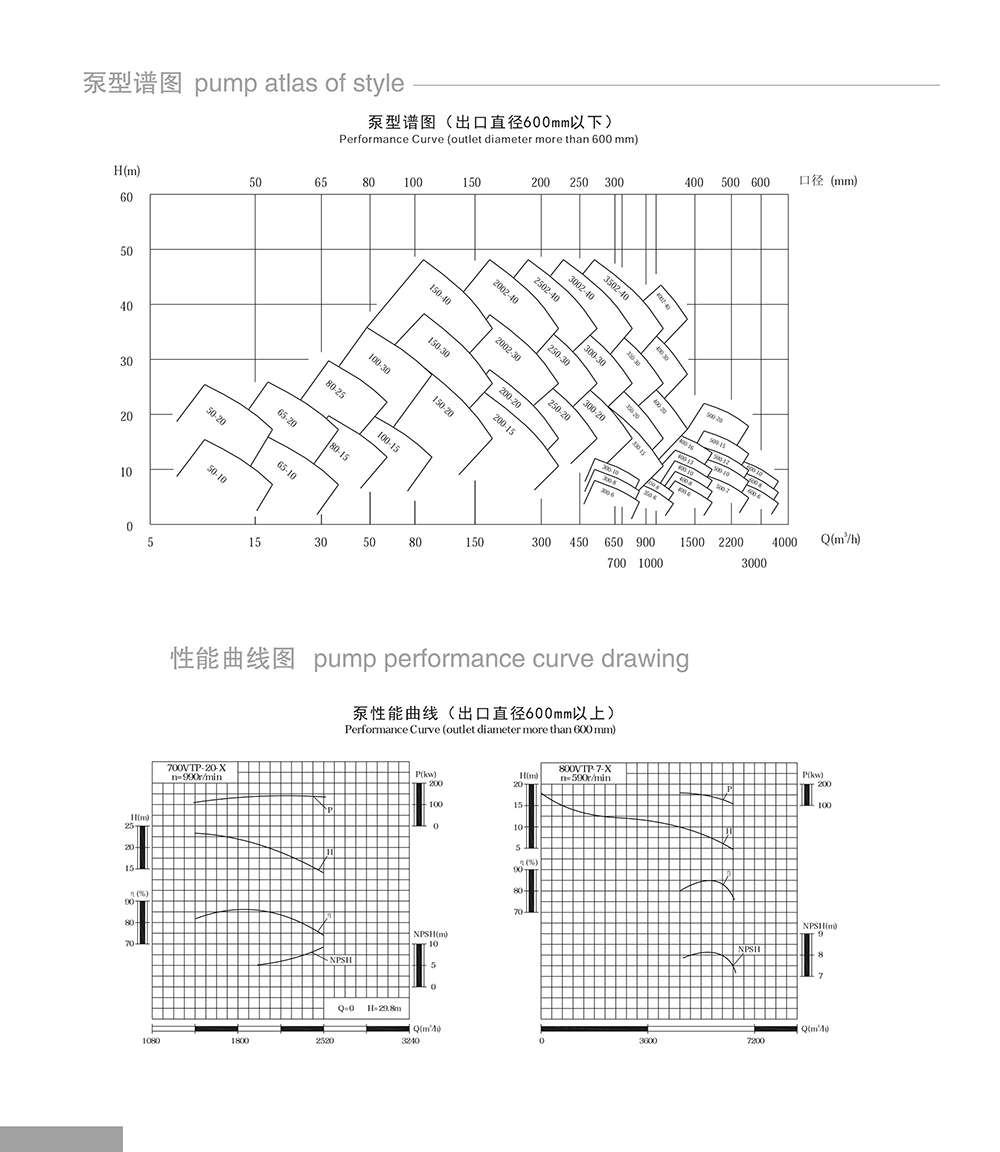

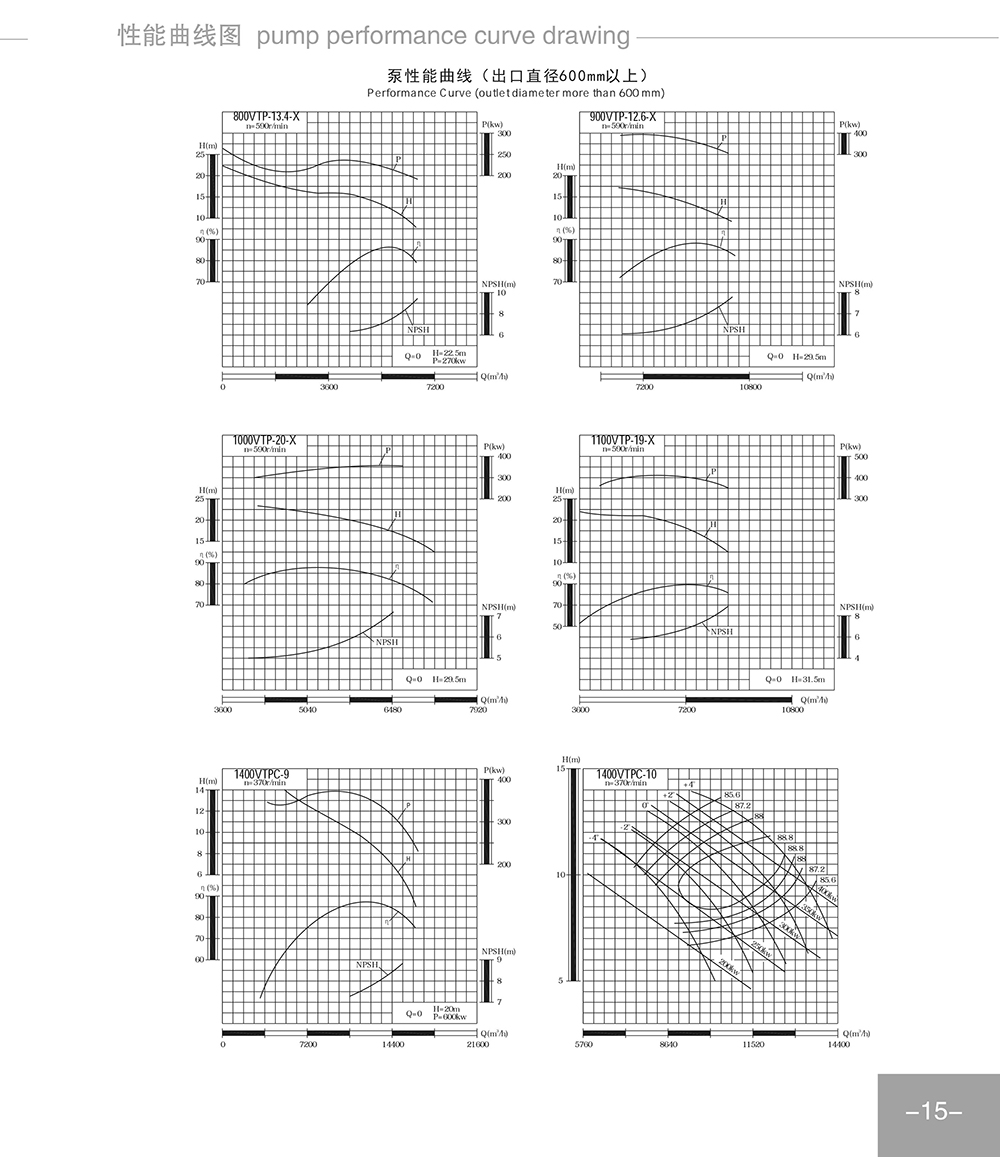

※ Imininingwane eyengeziwe ngochungechunge lwethu lwe-VTP i-Long Shaft Vertical Turbine Pump ye-curve nobukhulu kanye neshidi ledatha sicelathintana noTongke.

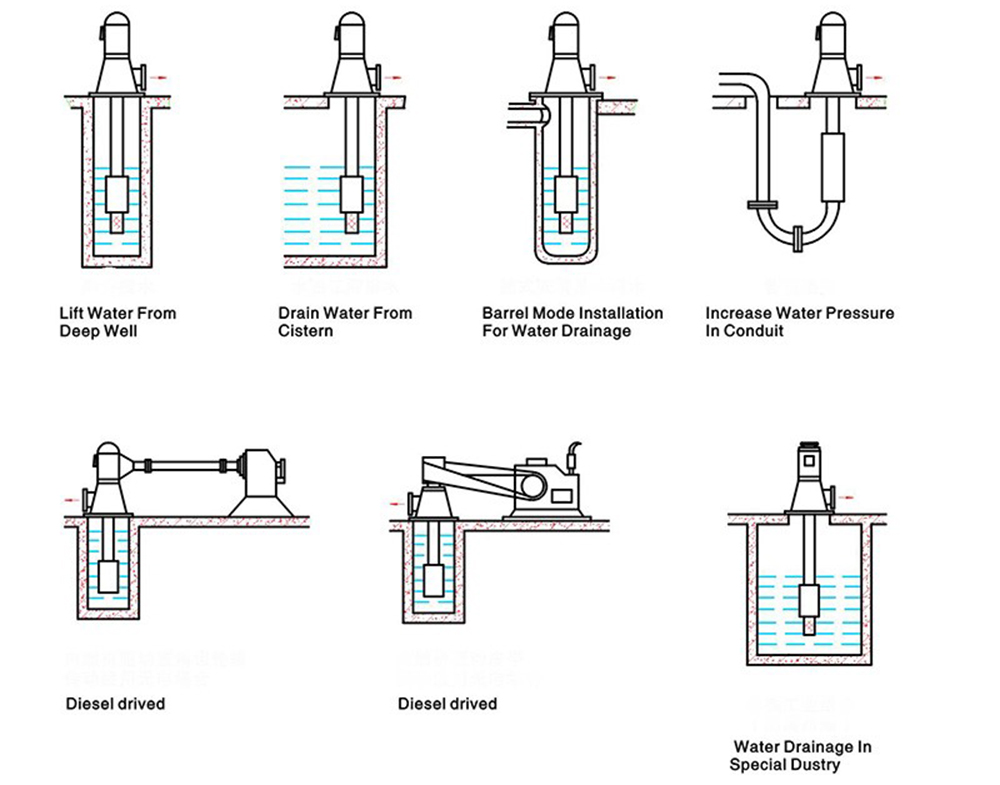

Indlela Esebenza Ngayo

Iphampu ye-turbine emile ivamise ukushayelwa yinjini yokungenisa kagesi ye-AC noma injini yedizili nge-engeli engakwesokudla. Ukuphela kwephampu kuqukethe i-impeller ejikelezayo ehlanganiswe ku-shaft futhi iqondise amanzi omthombo endaweni ye-diffuser eyaziwa ngokuthi isitsha.

Amaphampu anamalungiselelo ezigaba eziningi asebenzisa ama-impeller amaningana ku-shaft eyodwa ukuze akhiqize ukucindezela okuphezulu okungadingeka ukupompa amanzi emithonjeni ejulile noma lapho ukucindezela okuphezulu (ikhanda) kuyadingeka ezingeni eliphansi.

Iphampu ye-turbine emile isebenza lapho amanzi eza ngepompo esuka phansi ngedivayisi emise okwensimbi eyaziwa ngokuthi insimbi yokumunca. Amanzi abe esengena esigabeni sokuqala somfutho, okwandisa isivinini samanzi. Amanzi abe esehamba aye endaweni ye-diffuser ngqo ngaphezu kwe-impeller, lapho amandla esivinini esiphezulu eguqulwa abe ukucindezela okukhulu. I-diffuser casing iphinda iqondise uketshezi ku-impeller elandelayo etholakala ngqo ngaphezu kwekesi le-diffuser. Inqubo iqhubeka kuzo zonke izigaba zepompo.

Ulayini wepompo we-VTP ujwayele ukuklanywa ukuthi usebenze emithonjeni noma ezimpompini. Ukuhlanganiswa kwayo kwesitsha kuqukethe ikakhulukazi ikesi lokumunca noma insimbi, isitsha sepompo esisodwa noma ngaphezulu kanye nekesi lokukhipha. Umhlangano wesitsha sephampu ubekwe ku-sump noma emthonjeni ekujuleni ukuze unikeze ukucwiliswa okufanele.

FAQS

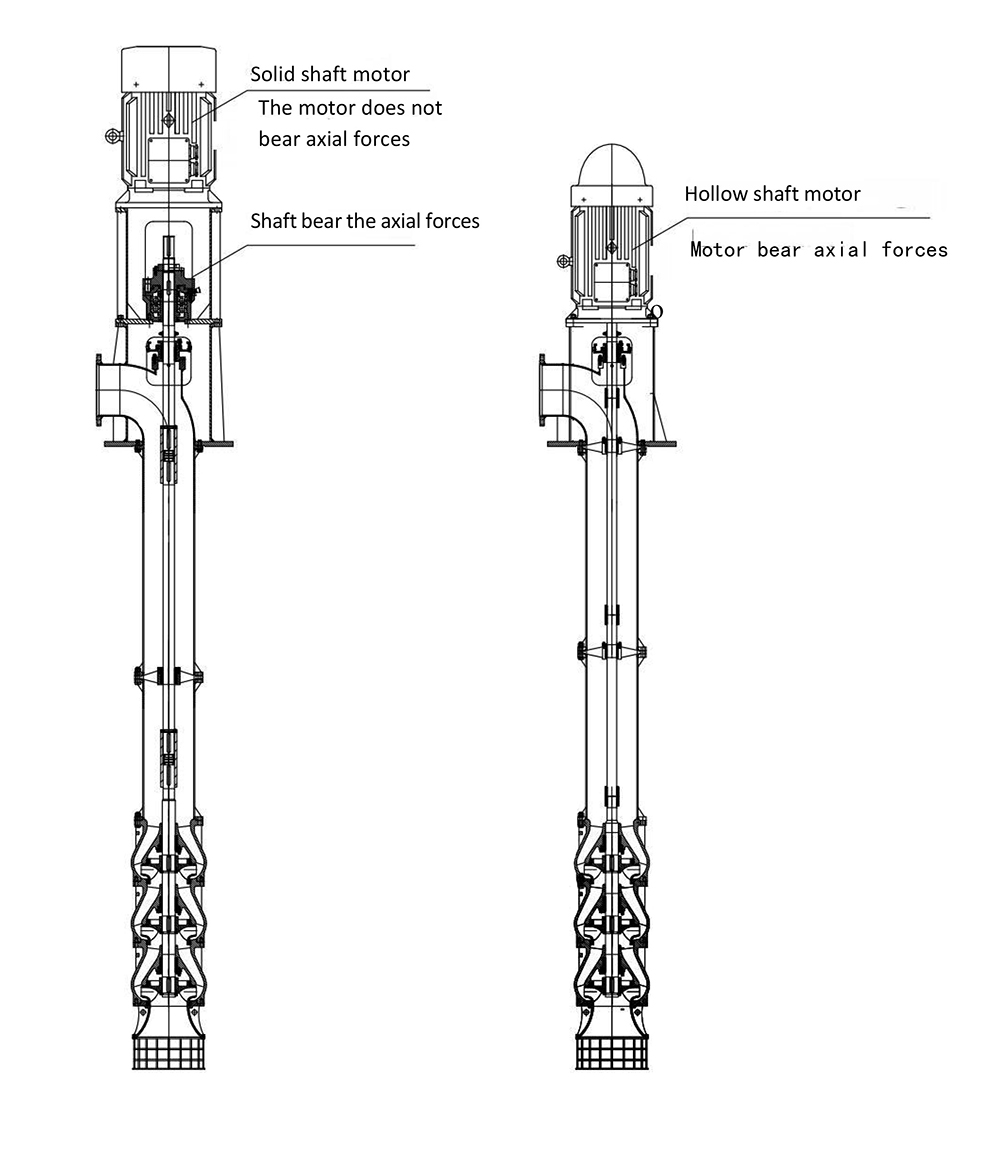

Iphampu ye-shaft eqinile

Isandiso se-shaft ngokuvamile sinendlela yokhiye oyindilinga yokudlulisa i-pump thrust, kanye nendlela yokhiye we-radial yokudlulisa i-torque. Ukuhlangana kokugcina okuphansi kwenjini yepompo kanye ne-shaft yepompo kubonakala kaningi emathangeni nasemaphampu angashoni, esikhundleni sokusebenza komthombo ojulile.

Uyini Umehluko Phakathi Kwe-Vertical Hollow Shaft (VHS) Pump Motors vs. Vertical Solid Shaft (VSS)?

Imboni yokumpompa yashintshwa ngokwakhiwa kwenjini yepompo emile ekuqaleni kwawo-1920. Lokhu kwavumela ukuthi izinjini zikagesi zixhunywe phezulu kwephampu, futhi imithelela yayimangalisa. Inqubo yokufaka yenziwa yaba lula, futhi ngenxa yokuthi yayidinga izingxenye ezimbalwa, yayingabizi kakhulu. Ukusebenza kahle kwama-motor futha kukhuphuke ngo-30%, futhi ngenxa yokuthi ama-motor futha aqondile anenhloso ethile, ahlala isikhathi eside futhi athembekile kunozakwabo abavundlile. Ama-motor futha aqondile ngokuvamile ahlukaniswa ngohlobo lwe-shaft yawo, engenalutho noma eqinile.

Izici Zokwakha

Zombili izinhlobo zamamotha ephampu ziklanywe ngokusobala ukusebenzisa amaphampu eturbine aqondile, futhi ngokuvamile ane-P-base mount ngaphandle kwezinyawo. Izici zokwakha zamapompo amamotho aqondile zinethonya ekusetshenzisweni kwazo kanye nezidingo zokunakekela.

I-Hollow Shaft

Umehluko osobala kakhulu phakathi kwezinhlobo ezimbili zama-pump motors ukuthi enye ine-shaft engenalutho, eshintsha izici zayo zokwakha kusukela ku-shaft eqinile. Kumamothoni wepompo we-shaft angenalutho, i-head-shaft yepompo idlulela ku-motor shaft futhi ihlanganiswe endaweni yemoto. I-nati elilungisayo litholakala phezulu kwe-head-shaft eqondisa ukulawulwa kwamandla empompi empompi. I-bushing engaguquki ivamise ukufakwa ukuzinzisa futhi imise phakathi kwe-pump shaft ku-motor shaft. Uma iqalwa, i-pump shaft, i-motor shaft, kanye nehlathi elinyakazayo liyazungeza kanyekanye, okuholela ekuzinzeni kwemishini okuqhathaniswa nalokho kwenjini ye-shaft eqinile. Ama-motor wepompo ye-hollow hollow ayizinjini ezisetshenziswa kakhulu kumaphampu ajulile, kodwa abuye akhethelwe noma yikuphi ukusebenza kwepompo okudinga amandla okulungisa kalula.

Umphini Oqinile

Amamothoni epompo e-shaft aqinile axhumeke kuma-shaft epompo eduze kokuphela kwenjini. Isandiso se-shaft ngokuvamile sinokhiye oyindilinga wokudlulisa i-pump thrust, kanye nokhiye we-radial wokudlulisa i-torque. Ukuhlangana kokugcina okuphansi kwenjini yepompo kanye ne-shaft yepompo kubonakala kaningi emathangeni nasemaphampu angashoni, esikhundleni sokusebenza komthombo ojulile.

Uhlobo Lokufakwa Kwephampu Ye-Turbine Emile

Amanothi Ngaphambi Koku-oda

1. Izinga lokushisa eliphakathi nendawo akufanele libe ngaphezu kwama-60.

2. Indawo emaphakathi izoba phakathi nendawo kanye nenani elingu-PH phakathi kuka-6.5~8.5. Uma imidiya ingahambelani nezidingo, cacisa ohlwini lwama-oda.

3. Ngepompo yohlobo lwe-VTP, okuqukethwe kwezinto ezimisiwe phakathi nendawo kuzoba ngaphansi kuka-150 mg/L; yepompo yohlobo lwe-VTP, i-max. Ububanzi bezinhlayiya eziqinile phakathi nendawo buzoba ngaphansi kuka-2 mm futhi okuqukethwe kube ngaphansi kuka-2 g/L.

4. Iphampu yohlobo lwe-VTP kufanele ixhunywe ngamanzi ahlanzekile noma amanzi anensipho ngaphandle ukuze kugcotshwe i-rubber bear. Kumaphampu esiteji ezimbili, umfutho we-lubricant akufanele ube ngaphansi kokucindezela kokusebenza.

Isicelo

Izinjini zomoya ezimile zivame ukusetshenziswa kuzo zonke izinhlobo zezinhlelo zokusebenza, ukusuka emanzini ezinqubo ezinyakazayo ezitshalweni zezimboni ukuya ekuhlinzekeni ukugeleza kwemibhoshongo yokupholisa ezindaweni eziphehla amandla kagesi, kusukela ekumpompeni amanzi aluhlaza ukuze aniselwe, ukuya ekukhuphuleni umfutho wamanzi ezinhlelweni zokumpompa zikamasipala, kanye nakuzo zonke ezinye izinhlelo zokusebenza zokumpompa ongazicabanga. Ama-turbines angenye yezinhlobo ezidume kakhulu zamaphampu abaklami, abasebenzisi bokugcina, abafaka Osonkontileka, nabasabalalisi.

| Ezohwebo/Ezezimboni/ Ukuqeda amanzi | Amapaki Amanzi/Umfula/Ukuzungeza Amanzi Olwandle |

| Izitshalo Ezimoshayo/Ukuchelela Kwezolimo/Umbhoshongo Wokupholisa | Ukulawula Izikhukhula/Izifundo zikaMasipala/Igalofu/Ukuchelela ngotshani |

| Izimayini/Ukukhithika/Ukucisha umlilo | Iphampu ye-Petrochemical Industry/Imboni yokukhipha usawoti emanzini olwandle noma iphampu yamanzi anosawoti |

| Ubunjiniyela bukamasipala/Ukulawulwa kwezikhukhula zedolobha kanye nokukhipha amanzi | Ukwakhiwa kwemboni/ Ubunjiniyela bokuhlanza indle |

Iphrojekthi yesampula

Ijika

sales@tkflow.com

sales@tkflow.com